Collaboration with garment manufacturers is the lifeblood of any successful apparel business. Whether you are a designer releasing a new line or an importer scaling up production, the effectiveness of your relationship makes or breaks product quality, delivery deadlines, and overall price. Yet many brands falter—communications deteriorate, producing substandard goods; production delays disrupt introduction schedules; and unforeseen expenses challenge budgets. How then can you have a hassle-free manufacturing collaboration?

The key is to enter with a good plan and solutions in hand. In this article, we will walk you through the most important steps of working with garment manufacturers, from development to production.

The journey begins with product development—a critical phase where you lay the foundation for a productive partnership. When going to a manufacturer, you need to define your vision and match it with their capabilities.

Start by establishing what it is you want to achieve. Write down rough sketches, decide on your market, and create a budget that works. Manufacturers are not mind-readers, so the more specific you can be, the better they will be able to help. Ask yourself: Where am I coming up short? Is it finding fabric, patterning off, or costing it out? Identify these shortcomings and vocalize.

Having manufacturers involved in your creative process can also support this stage. Share your concepts early and get their input—they have deep input from years of manufacturing knowledge. For instance, if you’re designing custom formal wear, their expertise can refine your ideas into polished, production-ready designs. Having a clear vision with mutual understanding establishes a solid foundation for working together.

A tech pack is your production guide. This document should include technical illustrations, spec sheets, fabric and color options, and anything else your manufacturer needs to bring your design to life. Cutting corners on this process might save time in the short run, but it most often leads to costly errors later on—think mismatched dimensions or the wrong materials.

Make it your own, take it slow. Re-measure double, add in label files when needed, and define each piece all the way to the stitching style. Correctly prepared tech packs minimize errors and enable your manufacturer to become completely productive right away—especially for intricate styles like custom Smart Casual that blend comfort and sophistication.

With your designs done, pre-production is where collaboration is actual. Now, during this time, finding the best partner, entering into an agreement with them officially, and ironing out your product through samples occur.

Not all creators are the same. Some are masters of small runs for up-and-coming designers, and others are masters of mass production for larger labels. Match their strengths with your needs—do you require full-service support from pattern-making to finishing, or just cut-and-sew expertise?

In order to find the most compatible match, ask the correct questions first: "What do you work with?" "How long does sampling take?" "Do you have room for my deadline?" Their response will inform you about their ability and willingness to achieve your goals—like producing custom woman's wear tailored to specific demographics. Pay attention to how they speak, too—the first impression tends to reflect how the working relationship will be.

A solid contract is your guarantee. Set delivery schedules, quality standards, and payment terms clearly. Indicate what you do if there are delays in timelines or there are defects—transparency at this stage prevents future conflicts. For example, will you be paying 50% down payment and 50% on delivery, or through a phased timeline?

The aim is to save money and time for both sides. A well-drafted agreement enables you to focus on production and design rather than hurrying to fix miscommunications. Share your budget and expectations openly; a good producer will offer alternatives to make it possible.

Before mass production begins, you’ll need to review samples. This step is your chance to catch issues—whether it’s a fabric that feels off or a fit that’s not quite right. Document every change, from trims to sizing adjustments, and share detailed feedback with your manufacturer.

Sample approval can take a few rounds, so build extra time into your schedule. Rushing this risks a final product that misses the mark. Once you’re satisfied, give the green light with confidence, knowing your vision is on track.

With pre-production locked in, it’s time to shift gears to full-scale manufacturing. This phase demands careful oversight to ensure efficiency and timely delivery.

Good production starts with planning. Sequence activities like cutting, sewing, and finishing, and monitor availability of labor and material. Shortages at the last minute—like out-of-fabric situations in mid-run—will blow your schedule, so create some buffer in quantities on important pieces. Monitoring your factory from time to time keeps all this in balance.

Errors here can be expensive. Inadequate planning could result in wasted materials or idle labor, increasing costs. Be proactive—monitor progress and solve hiccups as they happen.

Payment terms are extremely varied—some makers want 60-70% downpayment to pay for materials, while others will accept a sales agreement tied to your purchase order. Negotiate what is comfortable with both sides and commit it to writing. Flexibility is important, but clarity isn't.

Shipping deadlines are equally important. Delays in shipping may congest storage or miss market opportunities, while being too early can strain your logistics. Plan ahead with your manufacturer to have raw materials and labor in place at the right times. A commitment to timing ensures a smooth process.

Despite planning, issues arise. Tackling them promptly solidifies your partnership and ensures production stays on schedule.

Material shortages and production errors are common woes. A missed delivery by a supplier can halt your cutting room, or an error in sewing can produce defective clothes. Avoid these by spreading your supply base—having alternate sources of material can be a lifesaver. Preproduction checks on designs with virtual prototypes also catch problems earlier, reducing costly repairs.

Plan ahead. Your best defense is planning ahead. Coordinate with your manufacturer to discuss their capacity and stock up on essentials for heavy-demand runs.

Time zones and communication breakdowns slow everything down. If your foreign manufacturer, the responses will be delayed. Emails get lost, and a few apps leave updates in isolation. Coordinate overlapping hours for live chats and use shared calendars to be on the same page.

Consistency is crucial—plan regular check-ins at times that work for both sides. A unified tool will come in handy too, batching changes so nothing slips through the cracks. Easy workflows and quick feedback loops keep projects flowing, distance notwithstanding.

The problems highlighted hereabove—broken comms, complex technical packs, delayed production—do not have to destroy your partnership. There are new solutions available that can simplify things, and platforms like Kutetailor are leading the charge. Designed for remote bespoke clothing, Kutetailor allows brands, designers, and tailors to work smarter, not harder.

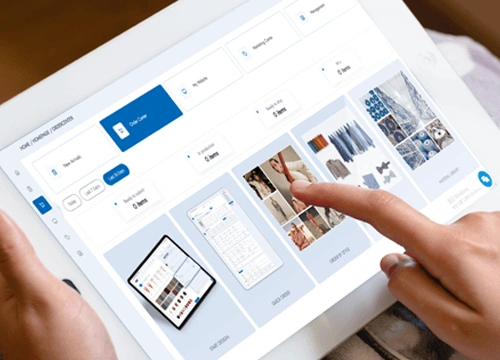

It is intimidating to create a tech pack or track orders, particularly for smaller teams. Kutetailor simplifies this with access to a vast library of garment patterns and craft details, enabling it to build correct designs more readily without needing to start from scratch. Ordering made to measure clothes online is also seamless—no coding skills needed. A graphical interface enables you to order bespoke suit or shirt and monitor real-time feedback on fabric availability and production status. This openness maximizes efficiency, enabling manufacturers to get exactly what they need to start production.

Disconnected communication loses time and potential for mistakes. Kutetailor addresses this by putting important information—order details, supply information, and progress reports—all in one location. You and your manufacturer can remain on the same page, avoiding back-and-forth emails or missed messages. Real-time control ensures you'll be aware in real-time if a delay is coming, so you can make swift changes. It's a sensible means of filling gaps and maintaining collaboration in smooth motion.

Aside from day-to-day operations, growing your business requires vision and adaptability. Kutetailor offers real-time reports that segment sales trends and customer preferences, enabling you and your manufacturer to concentrate on top-selling styles. For businesses looking to grow online, it enables rapid storefront deployment and automated marketing solutions to connect with customers effortlessly. This data-driven approach not only simplifies production but also enhances the overall experience, making your partnership more strategic and responsive.

Cooperating effectively with clothing manufacturers involves careful planning, effective communication, and problem-solving skills. From setting your vision in the product development stage to working through production and solving issues, each step builds a stronger partnership. Careful attention to detail—like a thorough tech pack or a clear agreement—pays off in quality and timely delivery.

More can be done with this by innovative tools. Platforms like Kutetailor offer designers, tailors, and retailers a smarter way to connect with manufacturers, simplifying workflows and boosting efficiency. Whether you’re refining designs or scaling up, the right strategies and solutions make all the difference. Ready to elevate your collaboration? Start by sketching out your next project and exploring tools suitable for your intent—your perfect partnership awaits.