Clothing manufacturing is a dynamic, rapidly evolving industry that involves creativity, craftsmanship, and cutting-edge technology. You may be reading this as an emerging designer designing your first collection, an established brand expanding production, or an entrepreneur looking at apparel business opportunities. You may be highly interested in the process of clothing manufacturing. This blog combines a thorough knowledge of history, a step-by-step approach to the manufacturing process, and some advice to remember to give you an overall idea of Clothing Manufacturing. Here is everything that you should know.

The story of the creation of clothing is a fascinating one from modest beginnings to worldwide giant. At one time, clothing was a labor of love—created by hand by people, and each item was unique and customized. That changed with the Industrial Revolution. The sewing machine developed during the 19th century automated the process and made it less labor-intensive. Mass production had started with the establishment of factories, and clothing had become a commodity available in bulk.

The 20th century brought more innovation: new synthetic materials like nylon and polyester expanded material options, and improved machinery improved efficiency. Clothing was more affordable and accessible than it had ever been. Today, the industry employs high-level technology—computers and robots assist in design and production, taking speed and affordability to new heights. But with these advancements, new problems have emerged. Growing concerns about sustainability and ethical labor practices are pushing manufacturers to redefine apparel manufacturing, balancing innovation with responsibility. Apparel manufacturing, from handmade to high-technology factories, continues to evolve to meet the needs and values of our world.

Essentially, clothing manufacturing is the process of converting raw materials into finished apparel through a series of operations like cutting, sewing, and finishing. It's a complex craft that divides into numerous sub-operations, each one intended to construct a specific garment. The exact operations can vary depending on equipment, production method, and the skills of the individuals involved. Whether it's a bespoke jacket or a t-shirt made in the thousands, this process is the lifeblood of the apparel industry, a union of creativity and attention to detail.

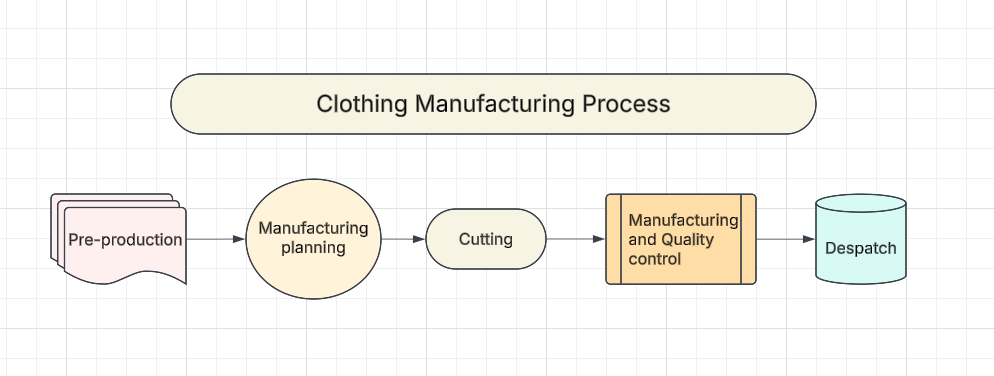

Clothing manufacture is a multifaceted process from designer idea to closet of customer. It goes through several key phases: pre-production (procurement of raw materials, pattern making, sampling), manufacturing planning (planning and scheduling of resources), cutting (preparation of fabric pieces), manufacturing and quality control (assembly and inspection of garments), and despatch (packing and distribution). Each phase supports the last, enabling efficiency and quality along the way.

It begins with the "Concept and Design" stage—the design hub of garment manufacturing. Designers take cues from fashion, culture, and innovative materials, sketching ideas that balance style and functionality. They experiment with color, texture, pattern, and aspects like silhouette, proportion, and harmony to craft wearable art. This stage sets the tone for the remainder of the process, dictating the journey from sketch to product.

Prototyping is where concepts materialize. Designers develop a pattern—a drawing outlining garment elements—and choose materials that fit their imagination. Fabric is cut, sewn into a prototype, and checked for fit, appearance, and touch. This first run provides leeway for making adjustments prior to mass production to ensure the finished product is aligned with the original idea and lives up to the expectations of the customers.

Samples play a critical role at various stages of clothing manufacturing, each serving a unique purpose in ensuring a garment’s design, fit, and durability are perfected. Below is a table outlining the different types of clothing samples and their specific roles in the process.

| Sample Type | Description |

| Mock-up Sample | Initial model to assess structure, often constructed from substitute fabrics to refine the silhouette. |

| Photo or Product Development Sample | A polished version in final fabrics and colors, used for promotional photography or further refinement. |

| Digital Garment Sample | A virtual representation created using software, previewing the design to save time and resources. |

| Fit Sample | Tests fit and comfort on a body, serving as the basis for adjustments to ensure optimal wearability. |

| Size Set Sample | Verifies that the design fits correctly across all sizes, ensuring consistency in style and comfort. |

| Salesman Sample | Used by sales representatives for presentations to buyers or at trade shows, often in select sizes. |

| GPT Sample | Evaluates durability (e.g., resistance to washing and wear) for "Garment Performance Testing." |

| Pre-production/Sealed/Gold Seal Sample | Final review before bulk production, using correct materials and trims to set the quality standard. |

| TOP Sample | First piece from the production run, ensuring alignment with expected quality and design specs. |

| Shipment Sample | Checked from the final batch to confirm the entire order meets high quality standards before shipping. |

| Press Sample | Created specifically for media and marketing purposes to showcase the garment publicly. |

| Proto-sample | Early design check using substitute materials to assess style and structure before finalizing. |

| Muslin Sample | A basic test using muslin fabric to evaluate the initial design concept and fit. |

Material buying is a make-or-break phase. Designers identify needs based on garment category (e.g., stretchy sportswear or streamlined custom formal wear), explore substitutes, and make contact with vendors via mills, trade shows, or wholesalers. Inspections for durability and colorfastness are next, with the samples being hand-tested. Common fabrics are cotton (voile, poplin, denim), viscose (crepe, satin), modal, hemp, linen, silk, etc., all in varying structure and weight. The right materials dictate the garment's comfort, durability, and appeal.

Pre-production is the basis for mass production. It entails approximating garment prices, creating and grading patterns, sourcing and testing raw materials, planning the manufacturing process, and producing approval samples. Efficiency is key here—without proper planning, production does not work. At this point, all the details are pre-determined before the factory goes into full production.

Production planning organizes manufacturing mayhem. Quantities are determined according to demand, budget, and storage by teams, and then schedules are set taking into account seasonal trends. Cutting and sewing operations are scheduled, materials (fabrics, threads) gathered, and labor assigned. Delays are compensated with backup plans, and progress monitored to make sure everything remains on track. This stage makes sure clothes reach the market at the right time.

Cutting and sewing give form to designs. Patterns are cut out to reduce waste, and fabric is cut. Cut pieces are prepared (marked, interfaced), then sewn together by experienced workers or machines in an assembly line. Finishing touches such as buttons, zippers, or embroidery are added, followed by ironing for a finished look. This combination of art and skill gives fabric wearable form, especially for styles like custom Smart Casual that blend versatility and precision.

Once cut and stitched, garments arrive at manufacturing and quality control. Assembly completes pieces, then follows rigorous inspections:

· Initial Check: Deters evident faults after sewing.

· Detailed Inspection: Evaluates fit, measurements, and specifications (i.e., stitches per inch—SPI).

· Functionality Test: Probes buttons, zippers, etc.

· Wash/Wear Test: Tests against wear and shrinkage.

· Fabric GSM Check: Measures density against specs.

· Material Composition Check: Confirms fiber content matches labels.

Quality Assurance (process-oriented) has quality in every step, while Quality Control (product-oriented) checks the finished product. A Purchase Order (PO) Sheet documents agreements, from materials to export. Apparel that passes all tests is finally approved.

The final stage prepares goods for consumers. After a final inspection, goods are folded, wrapped in tissue or biodegradable packaging, and labeled (size, care, barcodes). They're packaged in shipping boxes with shipping details and mailed by reliable carriers, often with tracking. Environmental packaging is evidence of growing environmental awareness, getting products to the consumer in perfect condition.

Shipping terms define responsibility:

· FOB (Free on Board): Costs to port are paid by the seller; buyer assumes risk upon loading.

· CIF (Cost, Insurance, and Freight): Cost, insurance, and freight paid by seller to destination; transfer of risk upon loading.

FOB is more suitable for sellers (lower cost), while CIF is more beneficial for buyers (package deal). Understanding these will aid in planning and budgeting logistics.

Collaboration is the foundation of apparel success. It unfolds in three stages:

1. Product Development: Designers create a business plan, visualize ideas, and develop a tech-pack.

2. Pre-production: Find a manufacturer, agree on terms, and produce samples.

3. Manufacturing: Plan shipments, manage labor, and oversee supplies.

Clear expectations from the start ensure a cohesive partnership.

A tech-pack—a collection of specs with sketches, measurements, trims, and labels—a maker's blueprint. Computer-Aided Design (CAD) simplifies sketching, pattern making, and planning, saving time from errors. Size charts ensure continuity in sizes, so communication is precise and manufacturing smooth.

Tech-pack and supplier list designers ask for quotes to meet budget, timeline, and quality. Weigh possibilities, barter for below-stated expenses (shipping, handling), and prioritize price with quality. Quoted in writing averts surprises, leading informed decision-making.

Sample terms avert expensive delay. Specify:

· Product details (CAD, BOM, sizes).

· Regulations and standards.

· Packaging/labeling needs.

· Revision count, costs, timing, refunds, NDA, and tooling ownership.

A well-drafted document saves time and money, ensuring sample viability.

Strong communication drives success. Be clear about needs, maintain regular updates, and provide honest feedback. Build trust through visits, mutual respect, and a long-term vision. A collaborative, problem-solving mindset fosters a partnership that grows with your brand.

4 – Choosing the Right Clothing Manufacturer

· Domestic: Faster turnaround, easier QC, supports local economy, lower carbon footprint; but higher costs, limited capabilities.

· International: Economical, scalable, broad selection; but longer lead times, communication problems, ethical issues.

· CMT (Cut, Make, Trim): Material supplied by brand; manufacturer cuts, sews, and trims. More work, more control.

· FPP (Full Package Production): Manufacturer does it all from sourcing through shipping. Hands-off, they trust their hand.

Beyond CMT and FPP, options include:

· Low MOQ: Ideal for small start-ups with low quantities.

· Mass Production: Created big brands and department stores.

Match the type to your scale and goals.

Assess:

· Capacity: Can they handle volume, scale, and rush orders?

· Quality: Consistent output, attention to detail, quick fixes?

· Sustainability: Eco-materials, waste reduction, ethical labor?

Prep your product info, timeline, and tech-pack, then:

· Define manufacturer type and quantity needs.

· Explore directories (e.g., Maker’s Row), trade shows, or regions (Asia, Americas, South Africa).

· Vet for fees, minimums, and logistics.

· Quality Control: Establish standards, organize checks, utilize third-party audits.

· Supply Chain: Have backup suppliers, stay knowledgeable, cultivate relationships.

· Communication: Keep it simple, frequent updates, cultural sensitivity.

· Production Defects: Reduce with planning, solve rapidly.

Proactive measures maintain production smooth.

Stay compliant with:

· Chemical registration, flammable fabrics, kids’ safety (under 12), textile standards, labeling, Fur/Wool Acts.

· Use audits, knowledgeable partners, and training.

Compliance builds trust and avoids legal pitfalls.

Labels must include:

· Country of origin, ASTM care instructions, fiber composition, brand/size/flag labels.

Accurate labeling ensures transparency and meets global rules.

The future is tech-driven:

· Machine learning, robots, and CRM optimize processes.

· Supply chain efficiency and rapid data analysis cut waste.

· 3D printing and AI enable customization; on-demand reduces stockpiles.

· Smart fabrics (color-changing, health-monitoring) innovate design.

These trends reshape how clothes are made and sold.

Sustainability is paramount:

· Ethical labor and better conditions fight fast fashion’s harms.

· Eco-materials (recycled, organic), azo-free/vegetable dyes, and resource conservation lower impact.

· Consumer demand rewards green brands with loyalty.

This shift saves the planet and boosts reputation.

1. Costs: Budget for design, licenses, equipment, staff, marketing.

2. Pricing: Research competitors, calculate cost per unit.

3. Marketing: Build a website, promote online.

4. Niche: Choose women’s, men’s, or kids’ apparel.

5. Planning: Select equipment, train staff if needed.

Clothing production is a journey from hand-sewn origins to high-tech, eco-friendly tomorrow. Mastering the process—design, make, collaboration—and choosing the right clothing manufacturer (like Kutetailor) can allow you to make quality clothing that resonates across the globe. Whether you’re creating made to measure clothes online or scaling a global brand, cooperate well, plan well, and collaborate sensibly—your clothing line awaits tomorrow's fashion with confidence.