Are you planning to launch your own clothing brand but unsure where to begin? Finding the right clothing manufacturers for startups is your very important first step! A reliable manufacturer will change your designs and ideas into tangible products and get your company smoothly off and running. This blog will guide you through the essential steps of choosing the ideal clothing manufacturer for your startup, ensuring a seamless transition from development to production. Additionally, we'll share key insights to support your decision-making process.

You should be very clear as to what kind of product line and brand identity you want for your startup before you contact any custom clothing manufacturers. Determine the kind of garments you will produce: casual wear, formal wear, or sportswear. Also, identify your customer segment. Is your brand going to be a FMCG, Light Luxury, or High-end luxury? For instance, if your focus is on high-end clothing, you may want to work with a manufacturer specializing in custom formal wear or custom Smart Casual. All this will help to understand the right manufacturer for the brand's goals and needs.

Estimate the Volume of Production and Budget

This is the second step in selecting an appropriate manufacturer where you need to assess your production volume and budget. Estimate the quantity of your initial production, keeping in mind to leave room for scalability. Allow appropriate funds for manufacturing, shipping, marketing, and other essential operations. Proper budgeting will help you sustain operations while growing the brand and adapting to demands.

Clarify the specific features and services you need from a manufacturer. Consider factors such as:

· Quality Standards: Ensure the manufacturer can meet your desired quality levels.

· Ethical Practices: Look for manufacturers committed to sustainable and ethical production.

· Minimum Order Quantities (MOQs): Choose manufacturers with MOQs that fit your startup’s capacity.

· Lead Times: Assess whether their production timelines align with your launch schedules.

· Additional Services: Decide whether you require design assistance or private labeling services.

With this knowledge, you can rule out potential partners that cannot cater to your specific needs. From our experience, the quality of a product is not to be compromised, and the finest manufacturers are indeed those that provide the highest quality with consistency.

Pros:

· Greater control over the production process

· Cost-effective for small batches

· High flexibility in design and materials

Cons:

· Requires sourcing your own materials

· Complex coordination and logistics

· Potential quality risks if not managed properly

CMT manufacturers specialize in cutting, making, and trimming garments based on the designs and materials you provide. This option offers flexibility and control, allowing you to customize every aspect of production. However, it requires more hands-on management and the ability to independently source high-quality materials. If you prioritize quality and need to maintain tight control over design details, the manufacturing process may require continuous monitoring. Moreover, the factory workers are not always well aware of your quality standard or minute design details, which could lead to a loss of fabrics and rough productions. Mediate these risks by negotiating a well-structured contract with the CMT manufacturer to limit your losses and ensure that quality meets your expectations.

Pros:

· Comprehensive services from design to production

· Streamlined communication and logistics

· Established supply chains and expertise

Cons:

· Higher costs compared to CMT

· Less control over certain aspects of production

· Greater dependency on the manufacturer

Full-package manufacturers are responsible for the entire production process, including design assistance, material procurement, production, and sometimes even distribution. This one-stop service approach simplifies operations and ensures consistency, making it an ideal choice for startups seeking efficiency and expertise. If you cannot afford to hire a professional designer or prefer to focus on other aspects of your business, a full-package manufacturer may be a better choice. You only need to provide general ideas and directions, and the manufacturer can help you design and manufacture your products.

Whether you're creating custom Women's Clothing or men’s tailored suits, ensure that the manufacturers have a proven track record in your specific area. Seek out those businesses that have been in operation for a number of years and who have a portfolio of satisfied clients. Experience often means better problem-solving skills and an understanding of the standards of the industry.

Today's buyers are conscious of sustainability and ethical manufacturing. Choose manufacturers with processes that appeal to values similar to your brand. Using eco-friendly materials, putting in place sustainable production techniques, and maintaining a workplace that is both fair and safe for employees will further your brand's reputation and meet the growing consumer demand for ethical products.

MOQs are pretty important for budgeting and managing inventory for your startup. These vary among manufacturers from a few hundred units to several thousand units. Find manufacturers with flexible MOQs so that you can test new designs without investing a lot in upfront costs. This flexibility is key for a startup that is trying to innovate rapidly and be agile.

Ensure the manufacturer can meet your current production needs and scale with your business as it grows. Check their production capacity to see if they can handle both small initial orders and larger, on-going production runs. Flexibility within the production process is important for accommodating changes or adjustments you may have.

Your manufacturer's location determines shipping costs, lead times, and communication. While domestic producers ensure quicker and simpler ways of shipping and effective communication, the advantages overseas can include lowered production costs, which come in higher capacities. Determine which fits better with each for your business' specific priorities and target market.

Online directories and B2B platforms are valuable resources for discovering potential manufacturers. Platforms like Maker’s Row, Alibaba, ThomasNet, and Kompass offer extensive listings of clothing manufacturers, allowing you to filter by location, production capabilities, and MOQs. These platforms also provide reviews and ratings to help assess the reliability of each manufacturer.

Trade shows and industry events offer the opportunity to meet manufacturers in person, discuss needs, and observe capabilities firsthand. Events such as MAGIC in Las Vegas, Première Vision in Paris, and Texworld are direct interactive platforms where you have the opportunity to build connections and get wind of the latest trend and technologies being followed.

Use your industry connections for referrals and to ask other brand owners, designers, and other professionals in the field. Networking on LinkedIn within fashion-focused groups or even at meetups may result in referrals you can trust to ensure you connect with very reliable manufacturers with a good delivery history.

Check the experience of each potential manufacturer in terms of equipment and production capability. Ensure they have all the relevant technology and know-how for making the type of garments you have in mind. For example, if you require complicated embroidery or sublimation printing, it is essential that the factory has the capacity to offer quality work in such areas.

You also request samples of past work the manufacturer has produced to have an idea about the quality of the work. You can be assured of good production quality if their portfolio looks good. Inspect their stitching, quality of the fabric used, color matching, and generally how the pieces are put together.

Verify the manufacturer’s compliance with industry standards by reviewing audit reports and certifications. Look for certifications like GOTS (Global Organic Textile Standard), WRAP (Worldwide Responsible Accredited Production), OEKO-TEX, and BCI (Better Cotton Initiative). These certifications indicate that the manufacturer adheres to quality, sustainability, and ethical standards.

Negotiating favorable pricing and payment terms is crucial for maintaining your startup’s budget. Discuss cost structures, potential discounts for larger orders, and flexible payment schedules. Common payment terms include partial payments upfront and the remainder upon delivery. Ensure transparency in pricing to avoid hidden costs.

Establish clear quality control measures to ensure that the product quality remains consistent. Establish inspection points, acceptance criteria, and procedures for addressing defects or discrepancies. Agree on regular quality checks and possibly third-party inspections to ensure high standards along the chain of production.

Intellectual property protection: Write contracts that protect your designs and brand identity. This means all designs, logos, and branding materials should be legally protected from being reproduced or shared by anyone else without your consent. Consider making an NDA, or non-disclosure agreement, to protect your proprietary information.

Keep the lines of communication with your manufacturer open and regular for the smooth running of operations. Also, use project management tools for tracking tasks, deadlines, and progress. Appoint one point of contact for smooth communication and to avoid misunderstandings.

Institute a process to monitor production progress and the quality of goods. Request progress reports, carry out inspections at key stages, and hire third-party quality control services if needed. This proactive strategy will help detect and resolve problems early in the production process.

Address issues promptly before they escalate. Foster open communication and a collaborative approach to problem-solving. Keep clear records of all correspondence and agreements to help resolve disputes and ensure accountability.

Communicate constantly with your manufacturing partner to develop trust and a long-term relationship. Schedule regular reporting and meetings not only to cover progress but also areas of concern or future orders. Clear communication equals respect and collaboration.

Perform regular performance reviews of the manufacturer on their quality, delivery times, and overall performance. Give constructive feedback where there is room for improvement and recognize excellent work. Invite feedback on how to make the partnership even better and continue improving.

Plan for scaling by discussing with your manufacturer about their ability to accommodate future needs for higher quantities or growth in order to scale accordingly with your business. In flexible agreements lies resource allocation for the growth trajectory of a startup.

Pros:

· No inventory costs

· Flexible production based on demand

Cons:

· Limited customization options

· Dependency on third-party quality

Print-On-Demand allows you to print garments only when an order is placed, and you don't have to deal with inventory management at all. It is a perfect model for startups to minimize their upfront costs and test new designs without significant financial risks.

Pros:

· No inventory management required

· Low upfront investment

Cons:

· Reliance on supplier reliability

· Potential quality control issues

Dropshipping involves partnering with suppliers who handle storage, packing, and shipping directly to customers. This model allows you to offer a wide range of products without the need for significant upfront investment. Platforms integrate seamlessly with online stores, enabling efficient order fulfillment. However, maintaining quality and timely delivery depends on the reliability of your suppliers.

Pros:

· Lower per-unit costs

· Bulk purchasing benefits

Cons:

· Higher initial investment

· Inventory management required

Wholesale buying is the process of buying garments in bulk from suppliers at a low cost. It is ideal for start-ups that want to maintain regular stock of merchandise and would like full control over inventory and branding. You can have your designs on the garments if you deal with reliable wholesalers. The profit margin in this model is greater, but you will need to invest upfront and manage your inventory efficiently.

Accurate estimation of the cost of manufacture is significant for financial planning. Consider material costs, labor costs, and overheads. Add up raw materials costs such as fabric, labels, sewing threads, and trims to manufacturing costs including labor and machinery. Such a detailed breakdown will help in setting appropriate pricing structures with the view of ensuring profitability.

Set aside a portion of your budget to get the products to where they need to be through marketing and distribution. Decide which marketing channels work best for your business goals and demographics. Consider how much will go into the distribution, such as shipping, storing, and selling. If these areas are done properly, then a clothing business can start to expand and grow.

Thus, shipment cost shares much importance in view of profitability and competitiveness related to the apparel business. Plan strategically for negotiation with the manufacturers and the shipment providers for better shipping rates and times of delivery. Minimise the cost of shipment by considering shipping location, volume, and method of shipment to maintain time for delivery. Efficient shipping strategy keeps the margin intact and leads to customer satisfaction.

The industry has also seen a recent uptick in domestic USA manufacturing, emphasizing high-quality, advanced technologies. Domestic manufacturers are able to provide better craftsmanship, quicker shipping times, and easier communication. Innovations such as laser cutting and sewing automation are increasing efficiencies in production. Generally, domestic manufacturing tends to be more expensive; however, the quality and ethical considerations have appealed to brands recently willing to invest in a more premium product.

Apparel manufacturing continues to be a powerhouse in Asia, with countries such as China, Vietnam, Bangladesh, and India leading from the front. China also gradually transformed from fast-fashion production to quality apparel production by commanding large-scale capabilities and advanced technologies. Vietnam has emerged due to its cost-effectiveness and increasing know-how in this field, while India enjoys a rich tradition of fabric arts combined with an ever-expanding fashion market. These countries balance cost and quality, making them attractive for startups that need large production capacities.

Central and South America are emerging as viable alternatives for apparel manufacturing, offering faster production turnarounds and favorable trade agreements. Countries such as Colombia, Peru, and Brazil are quite well-positioned in this regard, with unique raw materials and an expanding textile market. Proximity to the USA reduces the shipping costs and lead times, making these regions increasingly attractive to brands which are keen on holding fresh collections and responding to market trends with speed.

Africa is becoming a major player in the textile industry, and South Africa along with East African countries like Ethiopia and Kenya are taking significant interest in it. These countries offer sustainable and ethical production methods utilizing a large, growing labor force. The high-end value addition and governmental support make South Africa an attractive industry for growth, while countries like Ethiopia and Kenya have specialized in high-volume bulk basics, catering to the main export markets like the EU and the USA. With a focus on sustainability and ethical labor practices, Africa becomes an attractive option for brands focused on these values.

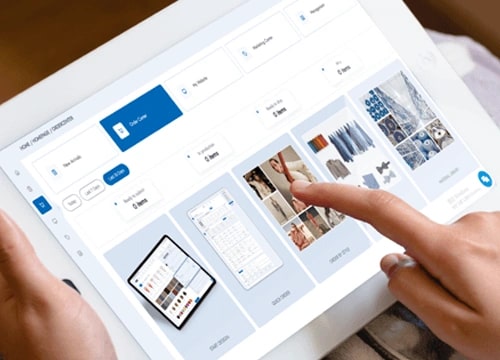

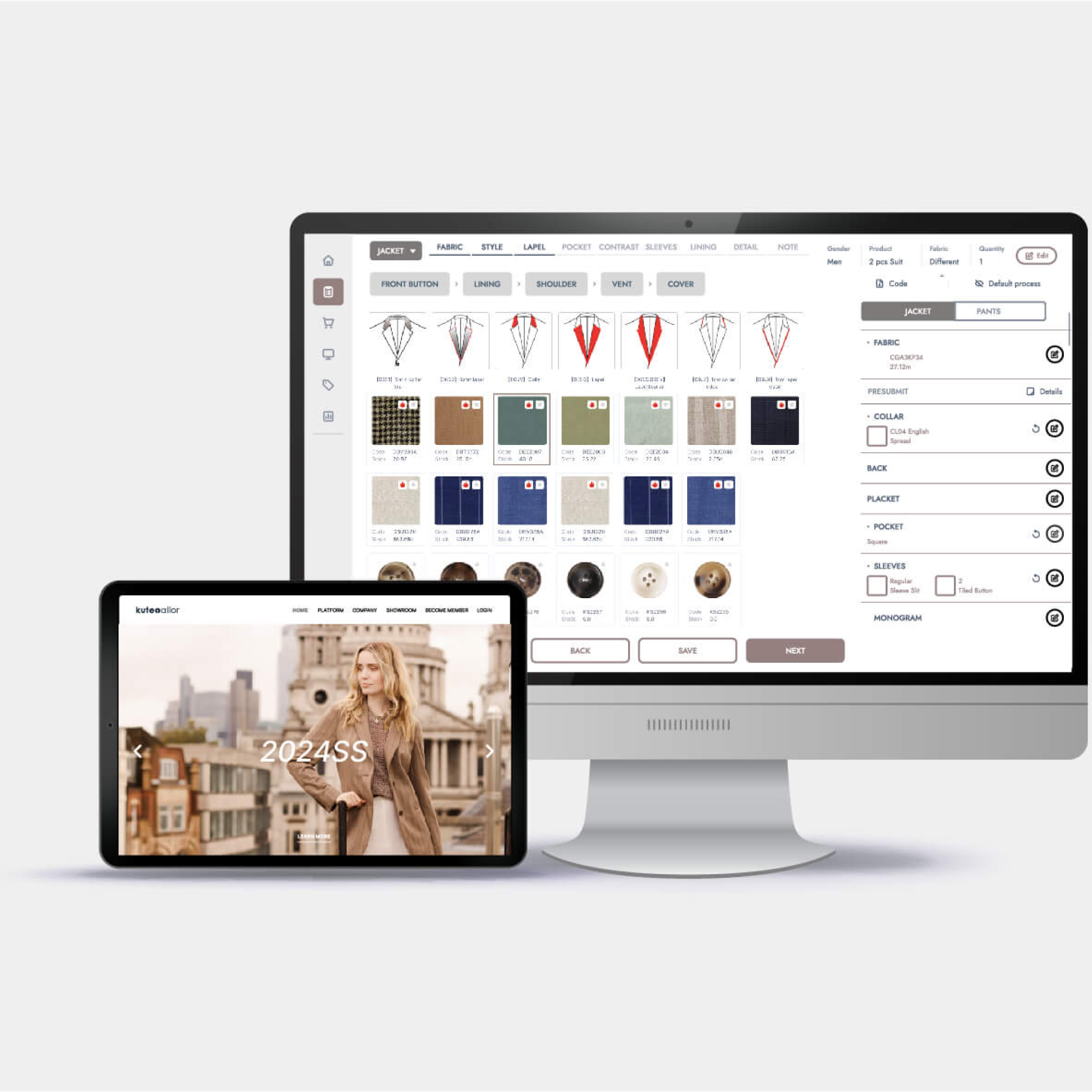

Startups are advised to go about selecting clothing manufacturers with as much research and strategic planning as possible. Find a few good partners through online resources, industry events, and referrals. Be very particular about the quality and ethics, and make a proper agreement that protects your interests. Strong, long-term relationships with manufacturers are important for your brand's growth and to maintain consistent product quality. If you have an idea, consider reaching out to Kutetailor. We have our own one-stop platform, which can provide you with the customization options you want and is your very reliable clothing supplier.

The best clothing manufacturers for startups are those with proven consistency, flexible MOQs, and assurances of quality and ethics in the production process. Do your research and consider potential partners in terms of experience, capability, and how well they align with your brand's values.

Reach out through online directories and B2B platforms like Maker's Row and Alibaba; attend trade shows; ask for referrals from colleagues in the industry. Do your due diligence, request samples, and check certifications to ensure reliability.

Include detailed product sketches, measurements, materials specifications, construction details, color palettes, and any other relevant specifications in a tech pack. This ensures accurate production, minimizing errors.

Clearly explaining your budget and production needs, negotiating payment schedules, asking for discounts for larger orders, and not having hidden or unclear pricing of any kind helps. You'll also be at an advantage while negotiating if there is a pretty good relationship between both parties.

Eco-friendly clothing manufacturers have a priority for sustainability and ethical practices that will enhance your brand's reputation, appeal to environmentally conscious consumers, and add to your long-term sustainability goals. In partnership with such manufacturers, the growing regulatory standards on sustainability will also be met.