In 2025, launching a fashion e-commerce brand means navigating a complex global supply chain where a single misstep can cost you customers and profits. From sourcing eco-friendly fabrics to delivering orders in days, the fashion supply chain is the backbone of any successful online apparel business. With consumers demanding transparency and sustainability, mastering your supply chain is more critical than ever. This guide explores how online fashion entrepreneurs can optimize their supply chains for efficiency, sustainability, and customer satisfaction in a rapidly evolving $1.5 trillion industry.

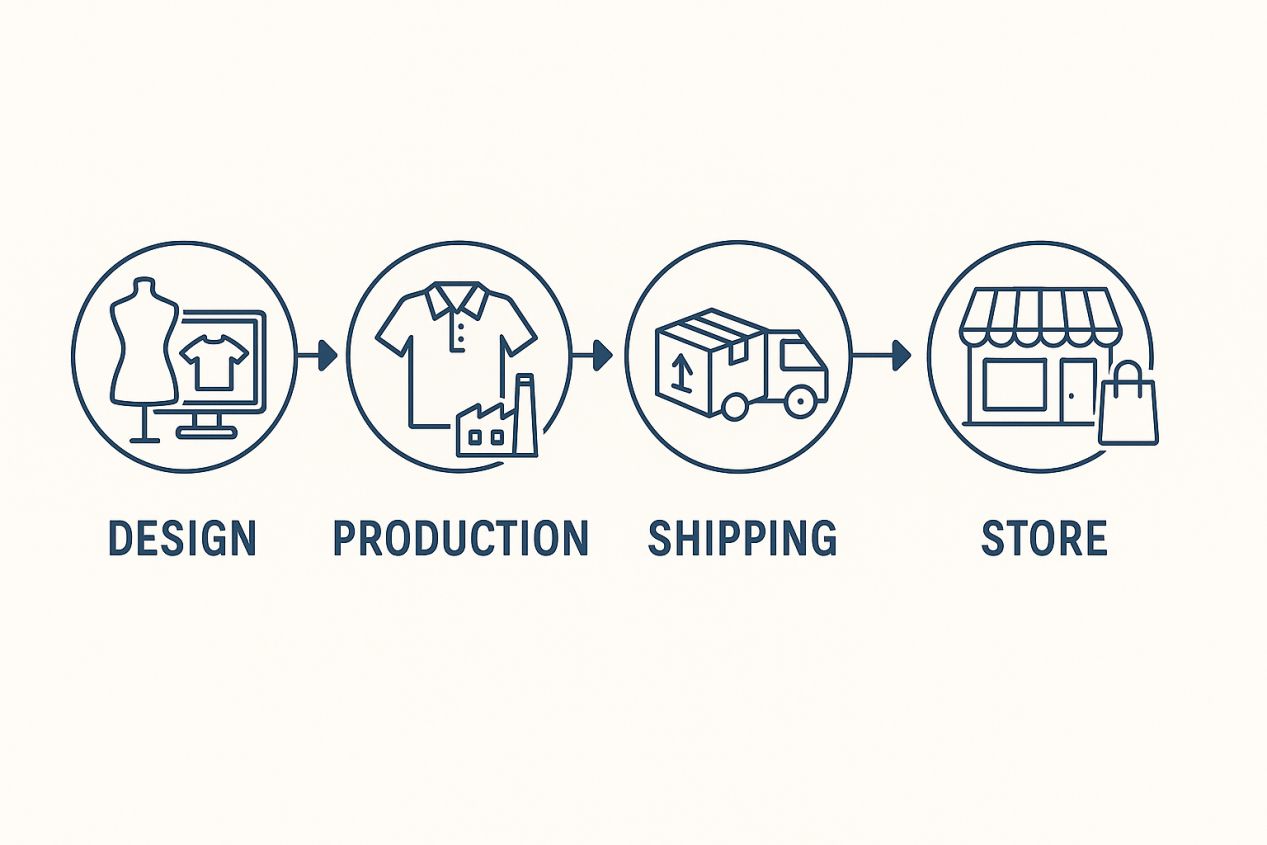

The fashion supply chain refers to the entire journey of a garment—from design and raw materials to production, shipping, and delivery. It’s a complex web of people, processes, and technologies that must work in sync to deliver your product to the end customer. For online businesses, it involves sourcing materials, manufacturing garments, managing logistics, warehousing, and fulfilling orders, all while meeting tight delivery windows and high return rates. Unlike traditional retail, e-commerce faces unique pressures: customers expect fast shipping, high return rates, and global competition.

The globalized nature of the apparel supply chain adds complexity. Raw materials might come from India, manufacturing from China, and sales from the U.S. or Europe. This sprawling network makes efficiency and transparency critical. A well-managed supply chain doesn’t just cut costs—it builds customer loyalty and strengthens your brand in a crowded market.

To thrive in e-commerce, you need to master each stage of the supply chain:

This is where it all begins. The design phase isn’t just about aesthetics—it’s also about functionality, material selection, production feasibility, and time-to-market. Product development involves:

l Trend research and mood boarding

l Sketching and technical design (CAD or tech packs)

l Prototype and sample creation

l Fit testing and revisions

A well-executed design and development process ensures your product is not only on-trend but also manufacturable and scalable.

Once your designs are finalized, you need to source materials and find the right manufacturing partners. This step involves:

l Selecting fabrics, trims, buttons, and labels

l Choosing suppliers based on cost, quality, and lead time is critical—especially when working with custom apparel suppliers who can meet your brand’s unique material and design needs.

l Negotiating contracts and MOQs (Minimum Order Quantities)

l Ensuring ethical and sustainable sourcing practices

For online fashion businesses aiming to appeal to conscious consumers, transparency and supplier reliability are critical.

This is the heart of the supply chain, where your garments are physically made. Whether you work with local workshops or overseas factories, key steps include:

l Fabric cutting and assembly

l Quality assurance at multiple checkpoints

l Compliance with safety and labor standards

l Batch testing and packaging

Efficient communication with your production partners and having a clear production calendar will help you avoid delays and unexpected costs.

Once your products are made, they need to reach your warehouse—or go directly to your customers. This stage includes:

l Freight forwarding (by air, sea, or land)

l Customs clearance and import/export documentation

l Warehousing and inventory management

l Order fulfillment and last-mile delivery

For e-commerce brands, fast and accurate fulfillment is crucial. Integrating your online store with your logistics system helps streamline operations and reduce fulfillment errors.

The final stage is where the product meets the customer—but your job isn’t done yet. This stage involves:

l Presenting products on your e-commerce site with high-quality images, descriptions, and size guides

l Managing customer service, inquiries, and returns

l Collecting feedback and using data to improve future designs

l Handling reverse logistics for returns and exchanges

Customer experience at this stage can make or break brand loyalty. A smooth delivery, easy returns, and excellent communication will turn first-time buyers into repeat customers.

Logistics is the backbone of your supply chain. In fashion, where trends change quickly, delays can cost you both money and credibility.

l Seasonal surges and unpredictable demand.

l Managing returns in a cost-effective way.

l International shipping complexities.

l Automated Warehousing: For faster, error-free order fulfillment.

l Smart Inventory Management: Avoid stockouts and overstock using demand forecasting tools.

l Reliable Fulfillment Partners: Work with 3PL providers that specialize in fashion logistics.

Tip: Offer multiple shipping options and clear return policies to enhance customer trust and satisfaction.

Unpredictable events—like pandemics, strikes, or raw material shortages—can severely disrupt your operations. An agile supply chain can adapt quickly to these changes.

l Diversify Suppliers: Don’t rely on one region or manufacturer.

l Develop Contingency Plans: Prepare backup logistics routes and stock reserves.

l Stay Informed: Use supply chain monitoring tools to detect potential disruptions early.

Agility also means being able to scale operations based on demand. This is where flexibility in production and fulfillment becomes vital for online retailers.

Digital tools are revolutionizing supply chain management in fashion. For online businesses, they enable speed, accuracy, and real-time decision-making.

l ERP (Enterprise Resource Planning): Unifies data across departments—inventory, sales, finance.

l Blockchain: Offers end-to-end transparency on sourcing and labor practices.

l AI & Analytics: Predict customer behavior, automate restocking, and personalize marketing.

l E-commerce Integrations: Connect platforms like Shopify or WooCommerce with inventory and fulfillment systems for seamless operations.

Bonus Tip: Choose fashion-specific tools like PLM (Product Lifecycle Management) software to streamline design-to-production workflows.

Running an online fashion business in 2025 comes with hurdles:

l Economic Pressures: Rising tariffs and inflation are squeezing margins, with 39% of fashion executives expecting tougher conditions this year.

l Supply Chain Disruptions: Geopolitical tensions, port strikes, and material shortages threaten delivery timelines.

l Consumer Expectations: Shoppers demand affordability, speed, and ethics—a tricky balance for small brands.

l Scalability: As your business grows, managing multi-channel sales (e.g., your website, Amazon, social platforms) requires robust systems.

To build a thriving online fashion brand, focus on these strategies:

1. Build Strong Supplier Relationships: Use supplier scorecards to evaluate performance on quality, ethics, and sustainability. Strong partnerships ensure reliability.

2. Invest in Technology: Adopt AI, RFID, or software like Inventory Planner to boost efficiency, even on a small budget.

3. Prioritize Transparency: Share sourcing details via tools like Digital Product Passports to build customer trust.

4. Optimize Logistics: Work with logistics providers for optimized routes and consolidated warehousing to save time and money.

5. Embrace Agility: Shorten lead times by emulating fast-fashion models, enabling quick responses to trends.

As you’ve seen throughout this guide, managing a fashion supply chain—from design and sourcing to fulfillment—requires agility, transparency, and reliable partners. If you're looking for a real-world tool to tie all these elements together, Kutetailor offers an integrated platform that simplifies the process for online clothing businesses.

Whether you’re building a brand that offers made to measure clothes online or managing small-batch production, Kutetailor supports you with:

l End-to-end production management with real-time tracking

l Visual customization tools for suits, shirts, and personalized apparel

l Flexible order processing and low minimums ideal for new or growing brands

l White-label store setup or API integrations for seamless online experiences

l Centralized dashboards for pricing, styles, and logistics

By integrating design, production, inventory, and fulfillment into a single system, Kutetailor helps modern fashion brands stay lean, agile, and customer-focused—especially in today’s volatile global market.

The fashion supply chain may seem complex, but for your online business, mastering it is essential. From ethical sourcing and streamlined logistics to smart use of technology, every step you optimize brings you closer to better margins, happier customers, and a more resilient brand.

Whether you're just launching your store or scaling your operations globally, building a supply chain that’s agile, transparent, and tech-enabled isn’t just smart—it’s the foundation of long-term success in fashion e-commerce.

Take the time to choose the right tools, partners, and strategies. And remember: fashion moves fast—but with the right supply chain in place, so can you.

It includes sourcing materials, manufacturing, logistics, inventory management, and order fulfillment. Online businesses must optimize for fast delivery and high return rates.

2. How do I manage high return rates?

Use prepaid return labels, recycle items, and apply AI quality control to reduce defects. Analyze return data to improve products.

3. How do I sync production with online sales data?

Use analytics to align production with real-time sales trends, creating feedback loops to adjust inventory dynamically and avoid overstock.