-

The Complete Guide to Custom Clothing Manufacturers: Everything You Need to Know

The Complete Guide to Custom Clothing Manufacturers: Everything You Need to KnowIn today's highly competitive fashion industry, more than ever, the need for custom clothing manufacturing has become critical. Manufacturers of custom clothes offer a special solution that will enable brands to differentiate themselves in the marketplace, as consumers demand more personalized and high-quality products. The key features of the process of manufacturing custom clothing will be discussed herein, which enables a business or an entrepreneur to understand the process, its benefits, and challenges while working with custom manufacturers.

What is Custom Clothing Manufacturing?

Custom clothing manufacturing generally refers to the process of producing clothes according to a customer's particular requirements. As opposed to mass production, which deals with standardized products, custom clothing is all about individualization. A custom manufacturer offers flexibility in new fashion lines, bespoke garments, or private label. It involves different stages, from design to pattern-making, the selection of fabrics, and stitching. It guarantees a quality, customized product that responds precisely to brand identity and consumer needs.

Services Offered by Custom Clothing Manufacturers

From design to production, custom-made clothing manufacturers often offer a range of services that can bring your fashion ideas into reality. These services might include:

· Sample Creation and Pattern-Making: Bespoke manufacturers help convert the initial design into a physical sample and pattern. They ensure the design fits into the intended aesthetic and fit.

· Fabric Selection: Based on the design requirement, manufacturers assist in choosing the best materials that will fit into both the aesthetic and functional needs.

· Full Package Production: Many custom manufacturers provide full-package services, right from trend research and design to production and logistics. This one-stop service has proved to be highly convenient, especially for those brands seeking one-stop solutions.

· Private Label Services: Besides this, the manufacturers provide private label service by manufacturing already designed garments and then allowing clients to put their own brand's labels, tags, and packing on them.

Types of Custom Clothing Manufacturers

Custom clothing manufacturers take on shapes and sizes in response to varied market needs. The common ones include:

· High-End Fashion Manufacturers: It deals with high-end clothes and pays more attention to minute details, finer fabrics, and impeccable finishing. Such a house is normally preferred by top-of-the-line brands that demand exclusivity and attention to detail.

· Streetwear and Fast Fashion Manufacturers: This category of manufacturers can produce fashionable clothes in the shortest time possible. They are meant for a fast-moving fashion industry where brands can keep up with the latest trends and satisfy consumer demand as soon as possible.

· Slow Fashion Manufacturers: Corresponding to sustainable fashion, the manufacturers of slow fashion are focusing on ethical production and high-quality garments with eco-friendly material. Such manufacturers are gaining more popularity due to the rising consciousness of consumers about sustainability.

· Sportswear Manufacturers: As athleisure and activewear continue to rise in popularity, manufacturers are adapting to produce high-performance garments that meet both style and functional needs.

The Geographical Advantage of Custom Clothing Manufacturers

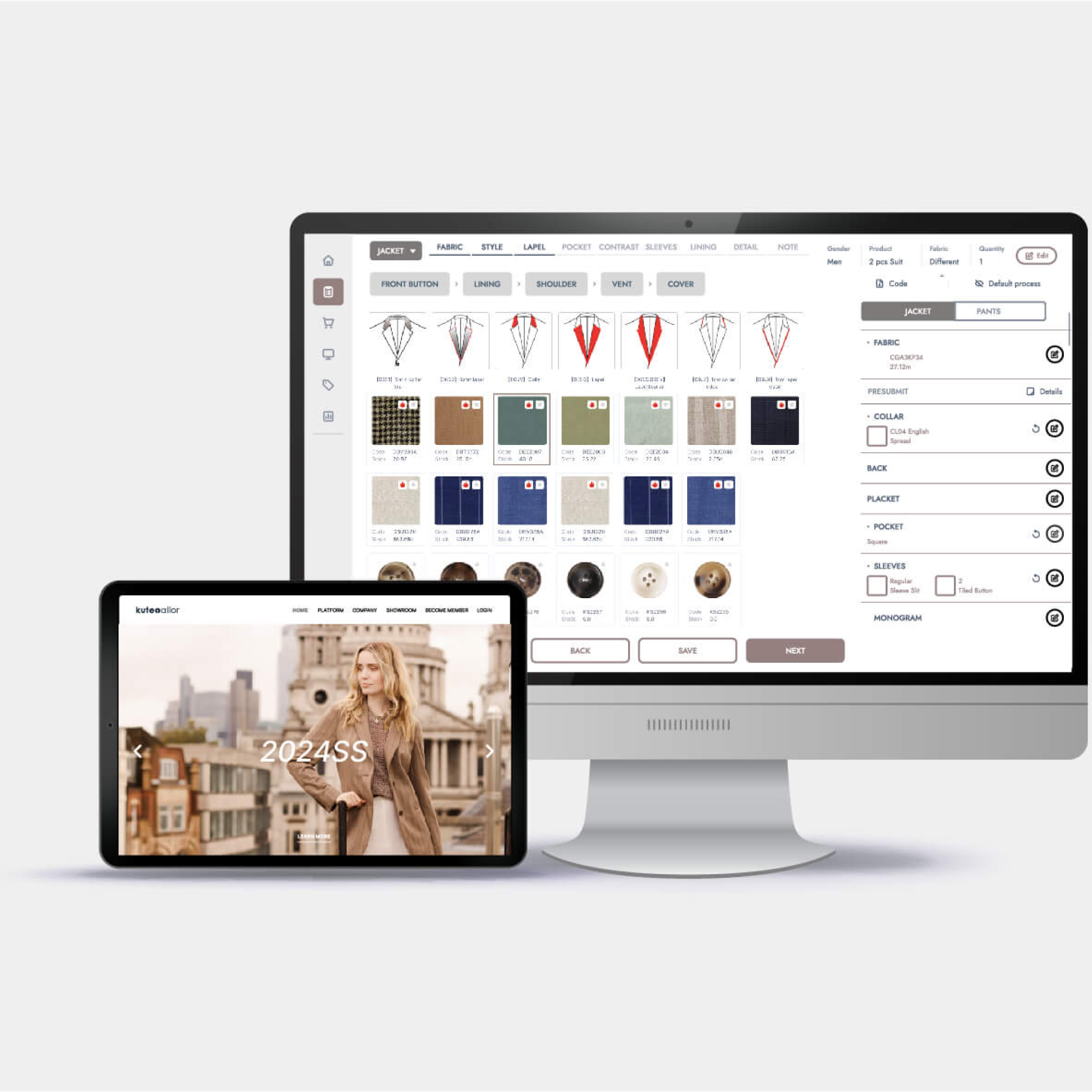

While cities like New York and Milan have long been considered fashion hubs, many custom clothing manufacturers are now making a significant impact in other regions, offering global reach and competitive advantages. One such example is Kutetailor, a China-based custom clothing manufacturer. By operating from China, Kutetailor takes advantage of the country’s well-established textile industry, vast manufacturing infrastructure, and cost efficiencies to provide high-quality, tailor-made apparel for fashion brands worldwide.

China has long been recognized as a key player in the global apparel manufacturing industry, thanks to its access to raw materials, experienced labor force, and advanced production technologies. In particular, Kutetailor leverages cutting-edge technology in its smart garment factory, offering a unique combination of intelligent tailoring, automated production, and a full-customization approach. This allows for fast delivery times—typically within 7-10 days—without compromising on quality. With transparent supply chains and a commitment to sustainable growth, Kutetailor ensures that each garment produced aligns with high standards, meeting the specific needs of brands while contributing to environmentally conscious practices.

Minimum Order Quantities (MOQ) and Cost Considerations

One of the key advantages of working with custom clothing manufacturers is their flexibility in terms of Minimum Order Quantities (MOQ). Unlike mass-market manufacturers that require large bulk orders, custom manufacturers often cater to small businesses, startups, and brands that need smaller production runs. This makes it easier for entrepreneurs to test their designs before committing to larger production quantities.

However, custom manufacturing costs may greatly differ in the varying factors that include design complexities, qualities of materials used, and levels of customization. For this, brands should be closely working with their manufacturers over discussing transparent pricing structures, negotiating for bulk discounts, and making sure that production costs fit their budgets.

Ethical and Sustainable Practices

With the rising concern for sustainability in fashion, most bespoke clothing manufacturers today have shifted much focus to ethics in production methods. Sustainable manufacturing practices can save waste, conserve resources, and reduce carbon footprint. Key areas of sustainable manufacturing of custom clothes include:

· Eco-Friendly Materials: Manufacturers help brands choose fabrics made from organic, recycled, or low-impact materials that contribute to environmental conservation.

· Fair Labor Practices: Ethical manufacturers ensure safe working conditions and fair wages for workers throughout the production process.

· Customization to Reduce Waste: Custom manufacturing allows brands to avoid overproduction and excess inventory, minimizing waste typically associated with mass production.

For businesses looking to appeal to environmentally-conscious consumers, partnering with manufacturers that focus on sustainability is an effective strategy.

How to Choose the Right Custom Clothing Manufacturer

The right custom clothing manufacturer will play a significant role in determining the success of your brand. Following are some of the key factors that you should consider while selecting a manufacturer:

· Research and Online Platforms: Utilize platforms such as Maker’s Row or Alibaba to search for manufacturers that match your requirements. These platforms offer detailed manufacturer profiles, allowing you to compare services, pricing, and past work.

· Experience and Reputation: Look for manufacturers with a proven track record in producing high-quality garments. Check customer reviews, testimonials, and portfolios to gauge their capabilities.

· Communication and Transparency: Effective communication is vital throughout the production process. Ensure the manufacturer is responsive and provides clear, transparent updates on timelines, costs, and production status.

· Samples and Quality Control: Request samples to check the quality and fit before committing to full-scale production. Quality control should be a big concern to make sure the final product is as desired.

The Custom Clothing Manufacturing Process

The manufacturing process for custom clothing involves several key stages:

1. Design and Pattern-Making: The process begins with the creation of detailed designs and technical specifications. These are then transformed into patterns that serve as blueprints for the garments.

2. Sampling and Prototyping: Samples are produced based on the patterns and designs to ensure the product meets the desired quality and fit.

3. Production: Once the samples are approved, production begins. Fabrics are cut, sewn, and assembled according to the design specifications.

4. Quality Control: Throughout the production process, stringent quality control checks are conducted to ensure that every garment meets the required standards.

5. Delivery: After passing quality checks, the finished garments are packaged and delivered to the customer.

Challenges in Custom Clothing Manufacturing

While custom clothing manufacturing offers many benefits, it also presents certain challenges:

· Quality Control Issues: Variations in craftsmanship, fabric quality, and design details can lead to inconsistencies. Regular inspections and third-party audits can help mitigate these issues.

· Production Delays: Delays in sourcing materials, production bottlenecks, or issues with shipping can cause delays. Building buffer time into the production schedule can help reduce the impact of delays.

· Communication Barriers: Misunderstandings between the brand and manufacturer can lead to errors. Clear communication and detailed specifications are essential for a successful collaboration.

Final Say

Custom clothing manufacturers are crucial in helping a brand come up with unique high-quality clothes that stand out in the market. The right manufacturer can help ensure that ideas come to life exactly as planned with the capability for scaling up production when needed. With increased awareness among consumers, pushing them toward sustainability and ethics in what they purchase, working with manufacturers who focus on these aspects will help the brand connect with the conscious consumer of today. With the right partner, custom clothing manufacturing offers endless possibilities for brand differentiation and growth.

MORE 2025-01-31 -

Haute Couture vs. Fast Fashion: A Clash of Craftsmanship, Culture, and Sustainability

Haute Couture vs. Fast Fashion: A Clash of Craftsmanship, Culture, and SustainabilityThe fashion industry is a complex ecosystem, spanning from exclusive handcrafted luxury to mass-produced affordability. This blog explores the stark contrasts between haute couture and fast fashion, while contextualizing their roles alongside ready-to-wear (RTW) and designer brands.

Haute Couture

Haute couture (French for "high dressmaking") represents fashion’s most elite tier. Each garment is handmade for a specific client, using luxurious fabrics like silk, lace, and hand-embroidered embellishments. Couture adheres to strict guidelines set by France’s Chambre Syndicale de la Haute Couture, ensuring only approved houses (e.g., Chanel, Dior) can use the label. A single piece can take hundreds of hours to create, with prices starting at $25,000.

For those seeking similar craftsmanship on a smaller scale, custom clothing manufacturers offer tailored solutions that balance quality and affordability.

Designer Brands

Designer brands like Gucci and Prada occupy the tier below haute couture. Their ready-to-wear (RTW) collections blend creativity with practicality, offering high-quality, trend-driven pieces at accessible (but still premium) prices. Unlike couture, RTW garments are produced in limited quantities for department stores and boutiques, targeting fashion-forward consumers who value both aesthetics and functionality.

Fast Fashion

Fast fashion—exemplified by brands like SHEIN and H&M—prioritizes speed and low cost. Garments are churned out in factories using cheap labor and synthetic materials, often replicating runway designs within weeks. While democratizing access to trends, this model fuels overconsumption: the average fast fashion item is worn just 7–10 times before being discarded.

Historical Evolution

From Royalty to Red Carpets: The Legacy of Haute Couture

Haute couture traces its origins to 19th-century Paris, where Charles Frederick Worth became the first designer to sew labels into his creations. Historically, it served European royalty and elites like Louis XIV, who used clothing to project power. Today, couture remains a status symbol for celebrities (e.g., Lil Nas X’s 2021 Met Gala Versace armor) and billionaires.

For modern consumers, custom formal wear offers a way to capture this exclusivity for special occasions like weddings or galas.

Fast Fashion’s Rapid Rise

Fast fashion emerged in the 1970s but exploded in the 2000s with globalization and social media. Platforms like Instagram accelerated trend cycles, normalizing a “wear-once” mentality. Brands like Zara mastered “micro-seasons,” releasing 36 collections yearly to capitalize on fleeting trends.

Production Processes: Quality vs. Quantity

Haute Couture: A Labor of Love

Couture garments begin with sketches, followed by meticulous fabric selection and multiple client fittings. Master artisans hand-cut and sew each piece, ensuring precision—a stark contrast to fast fashion’s automated assembly lines. As one article notes, “A couture dress outlives its wearer, often becoming an heirloom.”

Fast Fashion: The Cost of Speed

Fast fashion relies on global supply chains to minimize costs. Polyester and nylon—derived from fossil fuels—account for 60% of materials, while toxic dyes pollute waterways. Garments are often produced in sweatshops, where workers earn less than $3/day. This model generates 92 million tons of textile waste annually.

Economic and Cultural Impact

The Price of Exclusivity

Couture and designer brands thrive on scarcity. A 25,000 gown isn’t just clothing—it’s art. Meanwhile, RTW caters to aspirational shoppers willing to splurge on a 2,000 Prada bag. Fast fashion, however, thrives on volume: a $10 shirt may seem affordable, but its hidden environmental and social costs are staggering.

Consumer Psychology: Identity vs. Immediacy

Couture clients seek self-expression through unique pieces, while fast fashion shoppers chase the dopamine rush of newness. As Marc Jacobs noted, “Fashion is a whim—you don’t need it, you want it.” This dichotomy highlights deeper cultural values: craftsmanship versus convenience, permanence versus disposability.

Sustainability: The Industry’s Crossroads

Fast Fashion’s Environmental Toll

Fast fashion contributes 10% of global carbon emissions and 20% of wastewater. Less than 1% of materials are recycled, with 85% ending up in landfills. While brands like H&M launch “eco-collections,” critics argue this is greenwashing—distracting from systemic overproduction.

Couture as a Sustainable Blueprint?

Couture’s made-to-order model minimizes waste, offering lessons for sustainable fashion. Emerging brands are adopting bespoke practices, using deadstock fabrics or upcycling vintage materials. However, scaling these methods remains challenging.

The Role of RTW and Designer Brands

Designer brands are increasingly embracing sustainability. Stella McCartney pioneers vegan leather, while Patagonia repairs garments to extend their lifespan. RTW brands like Eileen Fisher now offer recycling programs, signaling a shift toward circular fashion.

The Future of Fashion

Shifting Consumer Values

Younger consumers, particularly Gen Z, are rejecting fast fashion’s excess. Platforms like Depop and Vinted promote secondhand shopping, while hashtags like #HauteCouture inspire appreciation for craftsmanship. The “buy less, buy better” mantra is gaining traction.

Innovation and Responsibility

Technology could revolutionize sustainability: 3D printing reduces fabric waste, while blockchain ensures supply chain transparency. Meanwhile, certifications like Fair Trade and B Corp help consumers identify ethical brands.

On the whole

Haute couture and fast fashion represent the two poles of an industry at a crossroads. If couture is artistry and legacy, fast fashion represents the instant gratification demanded by modernity. The rise of sustainable RTW and designer brands offers a middle path: one that balances creativity, accessibility, and responsibility. As consumers and brands alike put a premium on ethics, the future of fashion may finally align with the health of our planet.

FAQ

1. What is the difference between haute couture and designer clothing?

Haute couture refers to exclusive, handmade garments tailored for individual clients using luxury materials, adhering to strict French legal standards (e.g., Chanel, Dior). Designer clothing, while high-end and creative, is mass-produced in limited quantities (e.g., Gucci RTW collections) and sold at premium prices. The key distinction lies in customization: couture is one-of-a-kind, while designer pieces are standardized.

2. Why is fast fashion so harmful to the environment?

Fast fashion relies on synthetic fabrics (e.g., polyester), which shed microplastics and take centuries to decompose. It also generates massive waste—92 million tons of textiles end up in landfills yearly—and uses toxic dyes that pollute waterways. Additionally, its rapid production cycles encourage overconsumption, with garments worn only 7–10 times on average.

3. How can I identify sustainable fashion brands?

Look for certifications like Fair Trade, GOTS (Global Organic Textile Standard), or B Corp. Sustainable brands often:

• Use organic/recycled materials (e.g., Patagonia’s recycled polyester).

• Practice transparency in supply chains (e.g., Everlane).

• Offer repair/recycling programs (e.g., Eileen Fisher).

Avoid brands promoting “micro-seasons” or ultra-cheap prices, as these signal unsustainable practices.

4. Is ready-to-wear (RTW) the same as fast fashion?

No. RTW refers to pre-designed, factory-made clothing sold in standard sizes (e.g., Prada’s runway collections). While RTW is mass-produced, it prioritizes quality and timelessness over speed. Fast fashion, however, focuses on copying trends rapidly with cheap materials (e.g., SHEIN’s 10,000+ weekly styles). RTW is pricier but more durable.

5. Why does haute couture cost so much?

Haute couture’s price reflects handcrafted artistry:

• A single gown can take 200+ hours to make.

• Materials like hand-embroidered lace or silk can cost thousands alone.

• Only ~2,000 clients worldwide can afford it, limiting economies of scale.

Each piece is an heirloom, designed to last decades—unlike fast fashion’s disposable items.

MORE 2025-01-30 -

Clothing Manufacturers vs. Clothing Distributors: Understanding the Key Differences

Clothing Manufacturers vs. Clothing Distributors: Understanding the Key DifferencesFor those about to open a business selling clothes, or simply to anyone interested in how the chain of supply works within fashion, the difference between cloth manufacturers and distributors needs to be understood. Both play essential roles in the fashion industry, but they serve distinct purposes. Having a good grasp of the terminology helps ensure you’re well-informed. In this blog, we'll dive into what each does, how they differ, and how to choose the right partner for your business needs.

What Do Clothing Manufacturers Do?

A clothing manufacturer is responsible for turning design ideas into tangible products. A clothing manufacturer produces clothing from raw materials. They manage the entire production process, including sample making, cutting fabric, sewing, and assembling garments. Their key responsibilities include:

- Design Development: In collaboration with designers, the development of samples and prototypes is done by making use of tech packs. Generally, if you don't have a designer, clothing suppliers nowadays also offer design services, which is great for startups.

- Material Sourcing: Finding the right fabrics, trims, and materials needed for production.

- Production: Handling cutting, sewing, assembling, and finishing garments.

- Quality Control: Ensuring products meet brand specifications and quality standards.

Pros of Working with a Clothing Manufacturer:

- Fully customized and unique design for a product.

- Better quality control and oversight.

- Most of the vertical manufacturers can also produce for clients and work as a contractor. Private label apparel production opportunities.

What Do Clothing Distributors Do?

A clothing distributor is an intermediary between the manufacturer and the retailer who buys in bulk and distributes through the right channels. More specifically, distributors ship products from point A, the manufacturer, to point B, the retailer, fashion brand, or customer. Also commonly referred to as wholesale clothing distributors. The major responsibilities of clothing distributors include:

Purchasing in Bulk: Buying in bulk from the manufacturers at wholesale prices.

- Inventory Management: Storing and organizing products efficiently.

- Logistics & Shipping: Delivering products to retailers or direct-to-consumer channels.

- Retail Partnerships: Helping brands get their products into physical stores or online shops.

Pros of Working with a Clothing Distributor:

- Lower upfront costs compared to manufacturing.

- Faster time to market with ready-made products.

- Logistics and inventory management will be streamlined.

One of the great benefits of wholesale is that clothing can appear in fashion brands’ stores and boutiques more quickly. Inventory can be moved quickly, and independent designers can get their products to market in a short period of time.

Likewise, if you’re a small business looking to make waves in the fashion world, wholesale clothing may not be for you. Why? Because there’s a better way.

Private Label Clothing: A Hybrid Model

For those companies that would like to find a middle ground between manufacturing and distribution, there is private label apparel. Under private label arrangements, brands can:

- Select pre-existing designs from a manufacturer.

- Customize the product with their branding (labels, colors, fabrics).

- Ensure exclusivity by negotiating agreements to prevent other retailers from selling the same design.

This model balances exclusivity with efficiency, hence its popularity among new fashion brands seeking cost-effective solutions. Private label apparel is faster and more cost-effective for brands that want to sell unique products without investing much in the design and development process.

Clothing Manufacturers vs. Distributors: A Comparison

Aspect Clothing Manufacturers Clothing Distributors Role in the Supply Chain Produces garments from raw materials Distributes ready-made garments Customization High – allows custom designs Limited – offers pre-made selections Investment Higher due to production setup costs Lower due to pre-made stock availability Control Over Product High – full control from design to production Low – limited influence on designs Lead Time Longer – requires development time Shorter – quick turnaround time Best For Unique branding & designs Quick market entry with minimal effort

How Manufacturers and Distributors Work Together

Often, the manufacturer and distributor are closely aligned in a working relationship. Some companies function as both manufacturers and distributors, providing services from production all the way through to distribution.

For example, most fashion brands create a custom line with the manufacturers and then utilize distributors to ensure proper logistics and retail product placement. This helps such products to move smoothly along the supply chain.

Choosing the Right Partner for Your Business

The first decision in selling clothing using either a manufacturer or distributor is: you can either make it or get a distributor for it. If you choose to manufacture them yourself, you will look for a cloth manufacturing company in order to meet orders. That might be time-consuming since you need to get concerned with all production aspects, although you have an upper hand when it comes to flexibility in prices and designs.

Other considerations:

- Your Business Model: Do you want unique designs or quick market entry?

- Budget: Manufacturing requires higher investment, while distribution has lower upfront costs.

- Scalability Needs: Distributors can scale operations quickly; manufacturers offer long-term control.

- Time to Market: Distributors are faster, while manufacturers offer higher quality customization.

Tips for Finding Reliable Clothing Manufacturers and Distributors

With a view to making sure your partnership is going to be successful, here's how you should go about selecting a clothing manufacturer or distributor:

- Do Your Research: Read reviews, request samples, and check references.

- Ask About Experience: Ensure they have experience in your specific product category.

- Understand Their Capabilities: Check if they offer additional services like quality control, customization, or logistics support.

- Negotiate Contracts: Ensure clear agreements are in place regarding timelines, pricing, and exclusivity.

If you are a startup that needs help finding the right partner, our How to Choose Clothing Manufacturers for Startups can be a valuable resource.

Conclusion

The difference between a clothing manufacturer and a distributor is important to understand for any smart business decisions in the fashion industry. Whether you are seeking full creative control through manufacturing or a hassle-free distribution solution, knowing your options will help you choose the right path. The decision of who to work with ultimately comes down to what your budget allows and your business priorities.

At Kutetailor, we help fashion entrepreneurs realize their ideas with the best cloth manufacturing services. Feel free to contact us today and discuss how we can take part in your clothing brand's success.

FAQs

Q: As a fashion startup, should I use a manufacturer or a distributor for my fashion brand?

A: Well, that would depend on what exactly one intends to achieve. If custom designs and brand identity are needed, then go for the manufacturer; if quicker access to products is your aim, then it should be the distributor.Q: Can a company be both a manufacturer and a distributor?

A: Yes, some businesses offer both services to streamline the process.Q: How do private label options differ from manufacturing?

A: Private label clothing allows customization on existing designs, while manufacturing involves creating unique products from scratch.Q: What is the minimum order quantity (MOQ) when working with a manufacturer?

A: MOQs vary depending on the manufacturer, but typically range from a few hundred to thousands of units.Q: How do I ensure quality when working with a manufacturer?

A: Request samples, visit production facilities if possible, and set clear quality control guidelines.MORE 2025-01-23 -

A Complete Guide to Morning Suits: Everything You Need to Know

A Complete Guide to Morning Suits: Everything You Need to KnowAs a groom, you may be thinking about wearing a morning suit for your upcoming wedding. Or, you may be a member of a wedding party who has been invited to a wedding and the invitation says "morning suit". So what is a morning suit? This blog covers everything you need to know about morning suits, so read on.

What Is a Morning Suit?

A morning suit, also known as a morning dress, a stroller suit or a morning coat, is a classic piece of formal menswear typically worn at daytime events. A morning coat is a traditional men's formal suit designed for daytime events, usually worn before 6pm. It is a staple of custom formal wear.

Originally, a morning suit was an equestrian dress. It was originated in the 19th century. It provided a choice for the aristocrats and upper-class gentry to wear to sporting events, including horse riding, and social parties. The morning suit had become subversively casual -- even racy. The cutout hem and buttons at the back were equestrian features. King George V is said to have opposed the morning suit due to these sporting features. He insisted on a more formal dress, the old Victorian dress. When his son, Edward VIII, ascended the throne in 1936, he broke with tradition by abolishing formal dress, making the morning suit the court's preferred attire.

Components of a Morning Suit

The modern morning coat consists of several key elements, each contributing to its distinctive formal look:

- Morning Coat: The signature part of a suit, featuring a single button and pointed lapels. It is cut in an "S" shape, accentuating the waist, and flares slightly in the back to form a distinctive swallowtail, with a long slit that drops below the knee. Morning coats are usually black or grey and are worn with matching or complementary trousers and waistcoats.

- Trousers: There are fewer rules about morning coat trousers than you might expect. Morning suit trousers are typically striped or solid, featuring a straight-leg cut with a sharp crease down the front. Traditional styles often include grey and black striped patterns. But if you want to be more unusual, you can also wear trousers in black and white houndstooth, shepherd's check, Prince of Wales check, windowpane or even chalk stripes.

- Waistcoat: A single-breasted or double-breasted waistcoat worn under a coat. Double-breasted vests can be worn with lapels, and single-breasted vests can be worn with or without lapels. Popular colors include gray, buff, and pastel shades to make a statement. The vest should not be too short, it should hit an inch below the waistband. High-waisted tailoring is encouraged to tuck neatly under the vest. Do try and stomach wearing braces to keep that high waistline where it should be, too.

- Shirt: A fitted dress shirt with a stiff collar, usually white or a light color. Sky blue or pale pink are also safe choices. A swallowtail collar is a top choice to complement the formality of the suit.

- Tie or Cravat: Usually a silk tie or bow tie, it adds a sense of formality and a personal touch.

- Shoes: Polished black oxfords are the traditional footwear choice for morning dress (your shoes must always be black).

- Accessories: Traditional accessories include a top hat, pocket watch, gloves, and a boutonniere for special occasions. A complimentary pocket square and buttonhole flower make for elegant finishing touches

Occasions to Wear a Morning Suit

Morning suits are reserved for formal daytime events where a high level of dress code is expected. Common occasions include:

- Weddings: The most popular event for morning suits, especially for traditional ceremonies.

- Royal and State Events: Morning suits are often worn at official functions, including royal garden parties and diplomatic events.

- Horse Racing Events: Prestigious races such as Royal Ascot require strict dress codes, with morning suits being a staple.

- Religious Ceremonies: Such as bar mitzvahs and confirmations, where formal dress is encouraged.

How to Maintain and Store a Morning Suit

Proper maintenance and storage are crucial to preserving the quality and longevity of your morning suit:

- Cleaning: Always dry clean your suit after major events to remove any dirt or stains.

- Storage: Store your suit in a breathable garment bag to prevent dust accumulation and fabric damage.

- Ironing: Use a low-heat iron with a cloth to maintain sharp creases and prevent fabric shine.

- Rotation: Avoid wearing the suit too frequently to preserve its structure and appearance.

Regular upkeep ensures your morning suit remains in pristine condition for years to come.

Common Mistakes to Avoid When Wearing a Morning Suit

While morning suits exude sophistication, certain missteps can diminish their impact. Common mistakes include:

- Improper Fit: A loose or overly tight fit can detract from the suit's elegance.

- Incorrect Shirt Style: Opting for casual shirts rather than formal dress shirts can undermine the suit's formality.

- Over-Accessorizing: Less is more when it comes to accessories; avoid overwhelming your look.

- Neglecting Shoe Polishing: A polished pair of shoes is essential to complete the ensemble.

All in all

In short, a morning coat is a timeless and elegant choice for formal daytime events. Understanding its components, proper fit and accessories ensures you make a lasting impression. Whether you are attending a wedding, a grand match or a formal event, a well-cut morning coat demonstrates class and sophistication that will stand the test of time.

At Kutetailor, we have various fabrics and constructions for you to choose from, and our tailors can craft a morning coat according to your needs and style. Sign up to our online platform today and customize how you want, seeing all the options online, or contact us to take the first step toward your perfect morning coat.

FAQ

Should I custom a morning suit for a wedding?

If you attend formal events, it is worth investing in one. Morning coats are best ordered custom-made to fit you.

What color waistcoat should I wear with a morning suit?

Grey, buff or pastel shades are traditional colors. In very formal occasions, light grey provides an eternity and classic alternative for a waistcoat.

Can I wear a morning suit without a tie?

No, a tie or cravat is an integral part of the formal appearance of the morning suit.

What’s the difference between a morning suit and a tuxedo?

A morning suit is worn for daytime formal events, while a tuxedo (black tie) is reserved for evening occasions.

How should a morning coat fit properly?

This should form an "S" shape, cinching in at the waist and flowing over the hips for a comfortable, but not binding, fit.

MORE 2025-01-22 -

Perfect Suit Sleeve Length: How Long Should Suit Jacket Sleeves Be?

Perfect Suit Sleeve Length: How Long Should Suit Jacket Sleeves Be?One of the most critical details in achieving a polished and sophisticated look in a suit is getting the sleeve length just right. It might seem like a minor adjustment, but the length of your suit jacket sleeves can make or break the overall appearance of your ensemble. Follow this blog on determining the perfect sleeve length, how to adjust it if it's off, and learn how you can avoid these common pitfalls.

Why Does Suit Sleeve Length Matter?

When it comes to tailoring, the way your sleeves fit can make all the difference in how you look and feel in your outfit. For instance:

- Too-long sleeves make your jacket appear to be borrowed or too big, which defeats the whole point of looking sharp. A jacket that hangs on you doesn't do a good job of looking good.

- Too short sleeves make the jacket look like it doesn't fit; it's too small for you. It's like forcing a child's jacket onto an adult.

The correct proportion of jacket sleeve length and shirt sleeve length demonstrates that a man has control over his appearance, and who knew that good aesthetics is composed of these "small" details. So the sleeve length of a suit should be "just right", and the standard of "just right" is different for everyone, what is just right for one person may be too long or too short for someone else.

How Long Should Suit Sleeves Be?

So how long should a suit sleeve be? Simple rules of thumb on the length of a suit jacket sleeve:

- The sleeve should end just above the wrist bone, revealing a small portion of your shirt cuff.

- The shirt sleeve, in turn, should extend to the base of your hand, aligning with the wrist crease.

- Together, the visible shirt cuff should measure between 1/4 and 1/2 inch.

This rule creates a balance of styles between the jacket and shirt to avoid one from being overlapped by the other. For instance, in custom formal wear, such as tuxedos, people prefer wearing shorter sleeve jackets to top on cufflinks that add an elegance touch.

How Do I Know If My Suit Jacket Sleeves Are Too Short or Too Long?

Knowing the improper length of the sleeve is important:

- Too short: You can see the seam from where the cuff of your shirt meets the sleeve, or you have most of the cuff of your shirt visible, then your jacket sleeves are too short.

- Too long: No cuff of your shirt is visible, or the jacket sleeve covers part of your hand, then the sleeves are too long.

When putting on a suit, let your arms hang naturally down the sides. Proper sleeve length is not measured by raising or bending of the arms. If the suit jacket sleeve length sits just above your wrist bone, you don’t need to worry about how much the suit jacket moves up when you raise your arms.

How to Measure Suit Sleeve Length

Some menswear colleagues will ask you for your height and determine sleeve length based on that. While height often correlates to arm length, don’t just go with height! Be sure to measure your arm length. Measuring sleeve length accurately requires a flexible tailor’s tape. Follow these steps:

1. From Neck to Shoulder: Begin at the base of your neck at center, then measure over to the end of your shoulder.

2. From Shoulder to Wrist: Measure from the shoulder edge to the wrist bone, keeping your elbow slightly bent to mimic a natural posture.

3. Calculate Sleeve Length: Add the measurements for the shirt sleeve length. For the jacket sleeve length, subtract 0.5 inches from the shirt measurement to avoid covering the cuff.

Pro Tips:

- Do not measure over clothing to prevent errors.

- Check measurements double to ensure accurate measurements.

What Should I Do If My Suit Jacket Sleeves Are Too Long or Too Short?

If your jacket sleeves are not the ideal length, here’s what you need to know about adjustments:

- Shortening Sleeves: This is a pretty straightforward and common alteration that most tailors can do easily.

- Lengthening Sleeves: This depends on the extra fabric inside the sleeve. If there's not enough material, lengthening may not be possible.

- Functional Buttonholes: Jackets with functional buttonholes require adjustments from the shoulder, which is a more complex and expensive process.

If your sleeves are really short and next to nothing else can be done, it's time to buy a new one. A made-to-measure suit would be your best bet. “A man in a well-tailored suit will always shine brighter than a guy in an off-the-rack suit.” said the famous American designer Michael Kors. So, get a made to measure suit online that is just for you!

Sleeve Length and Accessories

Perfecting the sleeve length is also supported by accessories like watches. Whatever your suit sleeves might be perfectly matched with your dress shirt, there is always a problem in trying to fit in a watch into the picture. There should be sufficient space below the cuff for the watch to fit in comfortably, and the cuff should partially cover the watch when the arm is relaxed.

- Formal Settings: Accompany the suit with a timeless dress watch made from leather that comes with no pretension.

- Casual or Creative Vibes: Try a minimal or slim metallic watch.

In summary

The correct length of a sleeve for the suit is far from just about being comfortable. Rather, it shows style, self-confidence, and poise. In that regard, with knowledge about what is to be the best length and an even balance of the jacket cuffs to the shirt ones, elegance would shine at whatever the case might be. Whether for a formal event or a casual outing, the right sleeve length sets the tone for a sharp, refined look. We hope this blog on suit sleeve length can help you find the best suit style for you.

FAQ

1. How long should suit jacket sleeves be?

Suit jacket sleeves should end just above the wrist bone, with 1/4 to 1/2 inch of shirt cuff visible.2. How do I measure my suit sleeve length?

Measure across your neckline to shoulder level, then down to your wrist bone. Subtract the total by 0.5".3. Can a tailor adjust my sleeve length?

Yes, tailors can shorten or lengthen sleeves. However, lengthening depends on the amount of extra fabric available inside the sleeve.4. What if my jacket sleeves are too short?

Well, if it's too short-even if alteration won't be possible-it's best to buy another one that perfectly fits you.5. What is an average sleeve length?

For men, the average is around 32 to 33 inches. Of course, this is affected by body length, but this is just the average length.

MORE 2025-01-20 -

How to Choose Clothing Manufacturers for Startups: From Development to Production

How to Choose Clothing Manufacturers for Startups: From Development to ProductionAre you planning to launch your own clothing brand but unsure where to begin? Finding the right clothing manufacturers for startups is your very important first step! A reliable manufacturer will change your designs and ideas into tangible products and get your company smoothly off and running. This blog will guide you through the essential steps of choosing the ideal clothing manufacturer for your startup, ensuring a seamless transition from development to production. Additionally, we'll share key insights to support your decision-making process.

Understand the Needs of Your Startup

Define Your Product Line and Brand Identity

You should be very clear as to what kind of product line and brand identity you want for your startup before you contact any custom clothing manufacturers. Determine the kind of garments you will produce: casual wear, formal wear, or sportswear. Also, identify your customer segment. Is your brand going to be a FMCG, Light Luxury, or High-end luxury? For instance, if your focus is on high-end clothing, you may want to work with a manufacturer specializing in custom formal wear or custom Smart Casual. All this will help to understand the right manufacturer for the brand's goals and needs.

Estimate the Volume of Production and Budget

This is the second step in selecting an appropriate manufacturer where you need to assess your production volume and budget. Estimate the quantity of your initial production, keeping in mind to leave room for scalability. Allow appropriate funds for manufacturing, shipping, marketing, and other essential operations. Proper budgeting will help you sustain operations while growing the brand and adapting to demands.

Identify Key Requirements from the Manufacturer

Clarify the specific features and services you need from a manufacturer. Consider factors such as:

· Quality Standards: Ensure the manufacturer can meet your desired quality levels.

· Ethical Practices: Look for manufacturers committed to sustainable and ethical production.

· Minimum Order Quantities (MOQs): Choose manufacturers with MOQs that fit your startup’s capacity.

· Lead Times: Assess whether their production timelines align with your launch schedules.

· Additional Services: Decide whether you require design assistance or private labeling services.

With this knowledge, you can rule out potential partners that cannot cater to your specific needs. From our experience, the quality of a product is not to be compromised, and the finest manufacturers are indeed those that provide the highest quality with consistency.

Types of Clothing Manufacturers for Startups

Cut, Make, Trim (CMT) Manufacturers

Pros:

· Greater control over the production process

· Cost-effective for small batches

· High flexibility in design and materials

Cons:

· Requires sourcing your own materials

· Complex coordination and logistics

· Potential quality risks if not managed properly

CMT manufacturers specialize in cutting, making, and trimming garments based on the designs and materials you provide. This option offers flexibility and control, allowing you to customize every aspect of production. However, it requires more hands-on management and the ability to independently source high-quality materials. If you prioritize quality and need to maintain tight control over design details, the manufacturing process may require continuous monitoring. Moreover, the factory workers are not always well aware of your quality standard or minute design details, which could lead to a loss of fabrics and rough productions. Mediate these risks by negotiating a well-structured contract with the CMT manufacturer to limit your losses and ensure that quality meets your expectations.

Full-Package Manufacturers

Pros:

· Comprehensive services from design to production

· Streamlined communication and logistics

· Established supply chains and expertise

Cons:

· Higher costs compared to CMT

· Less control over certain aspects of production

· Greater dependency on the manufacturer

Full-package manufacturers are responsible for the entire production process, including design assistance, material procurement, production, and sometimes even distribution. This one-stop service approach simplifies operations and ensures consistency, making it an ideal choice for startups seeking efficiency and expertise. If you cannot afford to hire a professional designer or prefer to focus on other aspects of your business, a full-package manufacturer may be a better choice. You only need to provide general ideas and directions, and the manufacturer can help you design and manufacture your products.

Key Factors to Consider When Choosing Clothing Manufacturers for Startups

Experience and Track Record

Whether you're creating custom Women's Clothing or men’s tailored suits, ensure that the manufacturers have a proven track record in your specific area. Seek out those businesses that have been in operation for a number of years and who have a portfolio of satisfied clients. Experience often means better problem-solving skills and an understanding of the standards of the industry.

Sustainability and Ethical Practices

Today's buyers are conscious of sustainability and ethical manufacturing. Choose manufacturers with processes that appeal to values similar to your brand. Using eco-friendly materials, putting in place sustainable production techniques, and maintaining a workplace that is both fair and safe for employees will further your brand's reputation and meet the growing consumer demand for ethical products.

Minimum Order Quantities (MOQs)

MOQs are pretty important for budgeting and managing inventory for your startup. These vary among manufacturers from a few hundred units to several thousand units. Find manufacturers with flexible MOQs so that you can test new designs without investing a lot in upfront costs. This flexibility is key for a startup that is trying to innovate rapidly and be agile.

Production Capacity and Flexibility

Ensure the manufacturer can meet your current production needs and scale with your business as it grows. Check their production capacity to see if they can handle both small initial orders and larger, on-going production runs. Flexibility within the production process is important for accommodating changes or adjustments you may have.

Location Considerations

Your manufacturer's location determines shipping costs, lead times, and communication. While domestic producers ensure quicker and simpler ways of shipping and effective communication, the advantages overseas can include lowered production costs, which come in higher capacities. Determine which fits better with each for your business' specific priorities and target market.

How to Find the Best Clothing Manufacturers for Startups

Use Online Directories and B2B Platforms

Online directories and B2B platforms are valuable resources for discovering potential manufacturers. Platforms like Maker’s Row, Alibaba, ThomasNet, and Kompass offer extensive listings of clothing manufacturers, allowing you to filter by location, production capabilities, and MOQs. These platforms also provide reviews and ratings to help assess the reliability of each manufacturer.

Attending Trade Shows and Industry Events

Trade shows and industry events offer the opportunity to meet manufacturers in person, discuss needs, and observe capabilities firsthand. Events such as MAGIC in Las Vegas, Première Vision in Paris, and Texworld are direct interactive platforms where you have the opportunity to build connections and get wind of the latest trend and technologies being followed.

Networking and Referrals

Use your industry connections for referrals and to ask other brand owners, designers, and other professionals in the field. Networking on LinkedIn within fashion-focused groups or even at meetups may result in referrals you can trust to ensure you connect with very reliable manufacturers with a good delivery history.

Evaluating and Shortlisting Potential Manufacturers

Assessing Manufacturer Capabilities

Check the experience of each potential manufacturer in terms of equipment and production capability. Ensure they have all the relevant technology and know-how for making the type of garments you have in mind. For example, if you require complicated embroidery or sublimation printing, it is essential that the factory has the capacity to offer quality work in such areas.

Requesting Samples and Portfolios

You also request samples of past work the manufacturer has produced to have an idea about the quality of the work. You can be assured of good production quality if their portfolio looks good. Inspect their stitching, quality of the fabric used, color matching, and generally how the pieces are put together.

Audit Reports and Certification Review

Verify the manufacturer’s compliance with industry standards by reviewing audit reports and certifications. Look for certifications like GOTS (Global Organic Textile Standard), WRAP (Worldwide Responsible Accredited Production), OEKO-TEX, and BCI (Better Cotton Initiative). These certifications indicate that the manufacturer adheres to quality, sustainability, and ethical standards.

Negotiating Terms and Contracts with Clothing Manufacturers

Pricing and Payment Terms

Negotiating favorable pricing and payment terms is crucial for maintaining your startup’s budget. Discuss cost structures, potential discounts for larger orders, and flexible payment schedules. Common payment terms include partial payments upfront and the remainder upon delivery. Ensure transparency in pricing to avoid hidden costs.

Quality Control Measures

Establish clear quality control measures to ensure that the product quality remains consistent. Establish inspection points, acceptance criteria, and procedures for addressing defects or discrepancies. Agree on regular quality checks and possibly third-party inspections to ensure high standards along the chain of production.

Protecting Intellectual Property

Intellectual property protection: Write contracts that protect your designs and brand identity. This means all designs, logos, and branding materials should be legally protected from being reproduced or shared by anyone else without your consent. Consider making an NDA, or non-disclosure agreement, to protect your proprietary information.

Managing the Production Process

Effective Communication and Project Management

Keep the lines of communication with your manufacturer open and regular for the smooth running of operations. Also, use project management tools for tracking tasks, deadlines, and progress. Appoint one point of contact for smooth communication and to avoid misunderstandings.

Monitoring Production Progress and Quality

Institute a process to monitor production progress and the quality of goods. Request progress reports, carry out inspections at key stages, and hire third-party quality control services if needed. This proactive strategy will help detect and resolve problems early in the production process.

Handling Issues and Disputes

Address issues promptly before they escalate. Foster open communication and a collaborative approach to problem-solving. Keep clear records of all correspondence and agreements to help resolve disputes and ensure accountability.

Building Long-Term Partnerships with Manufacturers

Maintaining Good Communication

Communicate constantly with your manufacturing partner to develop trust and a long-term relationship. Schedule regular reporting and meetings not only to cover progress but also areas of concern or future orders. Clear communication equals respect and collaboration.

Regular Reviews and Feedback

Perform regular performance reviews of the manufacturer on their quality, delivery times, and overall performance. Give constructive feedback where there is room for improvement and recognize excellent work. Invite feedback on how to make the partnership even better and continue improving.

Scaling Production as Your Startup Grows

Plan for scaling by discussing with your manufacturer about their ability to accommodate future needs for higher quantities or growth in order to scale accordingly with your business. In flexible agreements lies resource allocation for the growth trajectory of a startup.

Alternative Clothing Manufacturing Options

Print-On-Demand (POD)

Pros:

· No inventory costs

· Flexible production based on demand

Cons:

· Limited customization options

· Dependency on third-party quality

Print-On-Demand allows you to print garments only when an order is placed, and you don't have to deal with inventory management at all. It is a perfect model for startups to minimize their upfront costs and test new designs without significant financial risks.

Dropshipping

Pros:

· No inventory management required

· Low upfront investment

Cons:

· Reliance on supplier reliability

· Potential quality control issues

Dropshipping involves partnering with suppliers who handle storage, packing, and shipping directly to customers. This model allows you to offer a wide range of products without the need for significant upfront investment. Platforms integrate seamlessly with online stores, enabling efficient order fulfillment. However, maintaining quality and timely delivery depends on the reliability of your suppliers.

Wholesale

Pros:

· Lower per-unit costs

· Bulk purchasing benefits

Cons:

· Higher initial investment

· Inventory management required

Wholesale buying is the process of buying garments in bulk from suppliers at a low cost. It is ideal for start-ups that want to maintain regular stock of merchandise and would like full control over inventory and branding. You can have your designs on the garments if you deal with reliable wholesalers. The profit margin in this model is greater, but you will need to invest upfront and manage your inventory efficiently.

Budgeting for Your Apparel Business

Estimating Manufacturing Expenses

Accurate estimation of the cost of manufacture is significant for financial planning. Consider material costs, labor costs, and overheads. Add up raw materials costs such as fabric, labels, sewing threads, and trims to manufacturing costs including labor and machinery. Such a detailed breakdown will help in setting appropriate pricing structures with the view of ensuring profitability.

Planning for Marketing and Distribution

Set aside a portion of your budget to get the products to where they need to be through marketing and distribution. Decide which marketing channels work best for your business goals and demographics. Consider how much will go into the distribution, such as shipping, storing, and selling. If these areas are done properly, then a clothing business can start to expand and grow.

Understanding the Impact of Shipping Costs

Thus, shipment cost shares much importance in view of profitability and competitiveness related to the apparel business. Plan strategically for negotiation with the manufacturers and the shipment providers for better shipping rates and times of delivery. Minimise the cost of shipment by considering shipping location, volume, and method of shipment to maintain time for delivery. Efficient shipping strategy keeps the margin intact and leads to customer satisfaction.

Global Manufacturing Trends and Regional Insights

Clothing Manufacturing in the USA

The industry has also seen a recent uptick in domestic USA manufacturing, emphasizing high-quality, advanced technologies. Domestic manufacturers are able to provide better craftsmanship, quicker shipping times, and easier communication. Innovations such as laser cutting and sewing automation are increasing efficiencies in production. Generally, domestic manufacturing tends to be more expensive; however, the quality and ethical considerations have appealed to brands recently willing to invest in a more premium product.

Clothing Manufacturing in Asia

Apparel manufacturing continues to be a powerhouse in Asia, with countries such as China, Vietnam, Bangladesh, and India leading from the front. China also gradually transformed from fast-fashion production to quality apparel production by commanding large-scale capabilities and advanced technologies. Vietnam has emerged due to its cost-effectiveness and increasing know-how in this field, while India enjoys a rich tradition of fabric arts combined with an ever-expanding fashion market. These countries balance cost and quality, making them attractive for startups that need large production capacities.

Clothing Manufacturing in Central and South America

Central and South America are emerging as viable alternatives for apparel manufacturing, offering faster production turnarounds and favorable trade agreements. Countries such as Colombia, Peru, and Brazil are quite well-positioned in this regard, with unique raw materials and an expanding textile market. Proximity to the USA reduces the shipping costs and lead times, making these regions increasingly attractive to brands which are keen on holding fresh collections and responding to market trends with speed.

Clothing Manufacturing in Africa

Africa is becoming a major player in the textile industry, and South Africa along with East African countries like Ethiopia and Kenya are taking significant interest in it. These countries offer sustainable and ethical production methods utilizing a large, growing labor force. The high-end value addition and governmental support make South Africa an attractive industry for growth, while countries like Ethiopia and Kenya have specialized in high-volume bulk basics, catering to the main export markets like the EU and the USA. With a focus on sustainability and ethical labor practices, Africa becomes an attractive option for brands focused on these values.

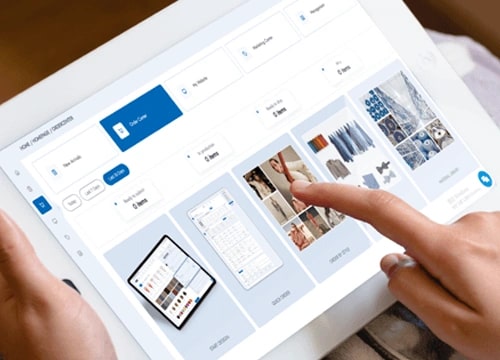

Final Advice for Startups

Startups are advised to go about selecting clothing manufacturers with as much research and strategic planning as possible. Find a few good partners through online resources, industry events, and referrals. Be very particular about the quality and ethics, and make a proper agreement that protects your interests. Strong, long-term relationships with manufacturers are important for your brand's growth and to maintain consistent product quality. If you have an idea, consider reaching out to Kutetailor. We have our own one-stop platform, which can provide you with the customization options you want and is your very reliable clothing supplier.

Frequently Asked Questions

1. What are the best clothing manufacturers for startups?

The best clothing manufacturers for startups are those with proven consistency, flexible MOQs, and assurances of quality and ethics in the production process. Do your research and consider potential partners in terms of experience, capability, and how well they align with your brand's values.

2. How do I find reliable clothing manufacturers for my startup?

Reach out through online directories and B2B platforms like Maker's Row and Alibaba; attend trade shows; ask for referrals from colleagues in the industry. Do your due diligence, request samples, and check certifications to ensure reliability.

3. What should I include in a tech pack for apparel manufacturing?

Include detailed product sketches, measurements, materials specifications, construction details, color palettes, and any other relevant specifications in a tech pack. This ensures accurate production, minimizing errors.

4. How can I negotiate better terms with clothing manufacturers?

Clearly explaining your budget and production needs, negotiating payment schedules, asking for discounts for larger orders, and not having hidden or unclear pricing of any kind helps. You'll also be at an advantage while negotiating if there is a pretty good relationship between both parties.

5. What are the benefits of working with eco-friendly clothing manufacturers?

Eco-friendly clothing manufacturers have a priority for sustainability and ethical practices that will enhance your brand's reputation, appeal to environmentally conscious consumers, and add to your long-term sustainability goals. In partnership with such manufacturers, the growing regulatory standards on sustainability will also be met.

MORE 2025-01-10