-

Top 10 Best Custom Apparel Companies and Clothing Manufacturers in 2025

Top 10 Best Custom Apparel Companies and Clothing Manufacturers in 2025The custom apparel industry is hotter than ever, with businesses and individuals craving unique, high-quality clothing. Whether you’re starting a brand, ordering event tees, or seeking sustainable solutions, the right supplier is crucial. Here’s our ranking of the top 10 custom apparel companies and clothing manufacturers for 2025, showcasing craftsmanship, versatility, and innovation. Let’s get started!

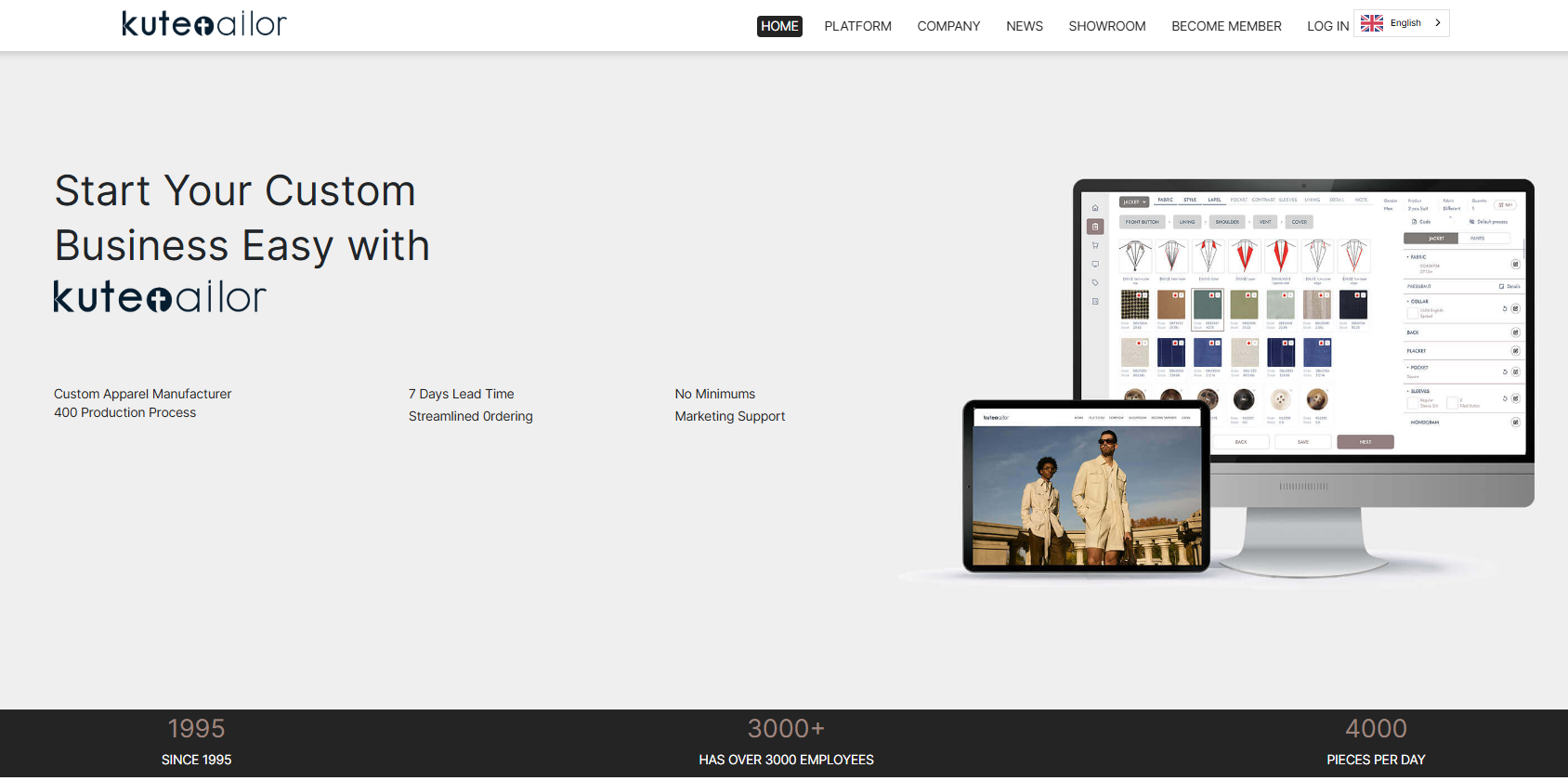

1. Kutetailor - Best for Bespoke Custom Clothing

Website: https://www.Kutetailor.com/

Kutetailor leads as a bespoke apparel innovator, delivering tailor-made suits and apparel for fashion brands and businesses via its one-stop MTM platform. Using sustainable practices, top-quality fabrics, and a pioneering smart factory, it offers self-design, intelligent tailoring, and automated production with delivery in 7-10 days. Kutetailor sets the bar for precision and eco-conscious excellence in 2025.

Pros:

· Deep customization (fabrics, fits, designs).

· Empowers clients with self-design tools and intelligent tailoring for suits and apparel tailored to perfection.

· Fast turnaround with global shipping. Achieves 7-10 day turnarounds thanks to cutting-edge automation and smart factory technology.

· Uses only the best materials, ensuring durability and a premium finish for every garment.

Summary:

Kutetailor excels in personalized apparel, making it ideal for startups and individuals seeking standout pieces.1. Fite Fashion - Best for Sustainable Custom Designs

Website: https://fitefashion.com/

Fite Fashion shines with its eco-friendly approach, crafting custom attire from sustainable fabrics with ethical production.

Pros:

· Eco-friendly materials and recycled packaging.

· Flexible design options.

· Free US shipping.

Cons:

· $25 flat fee for international orders.

Summary:

A top choice for green brands, Fite Fashion blends sustainability with high-quality customization.1. AEL Apparel - Best for Fast Custom Designs

Website: https://aelapparel.com/

AEL Apparel delivers trendy custom clothing with a speedy 7-20 day turnaround (3 days for rush orders).

Pros:

· Wide range (activewear, denim, swimwear).

· Free design consultations.

· Ethical production.

Cons:

· Large orders may extend lead times.

Summary:

Perfect for brands needing stylish apparel fast, AEL offers speed and versatility.1. Sumissura - Best for Tailored Women’s and Men’s Wear

Website: https://www.sumissura.com/

Sumissura brings bespoke clothing to life with 500+ fabric options and precise fits via an algorithm.

Pros:

· Extensive customization (pockets, buttons, linings).

· Free shipping over 120€.

· High-quality craftsmanship.

Cons:

· No shipping to Brazil.

Summary:

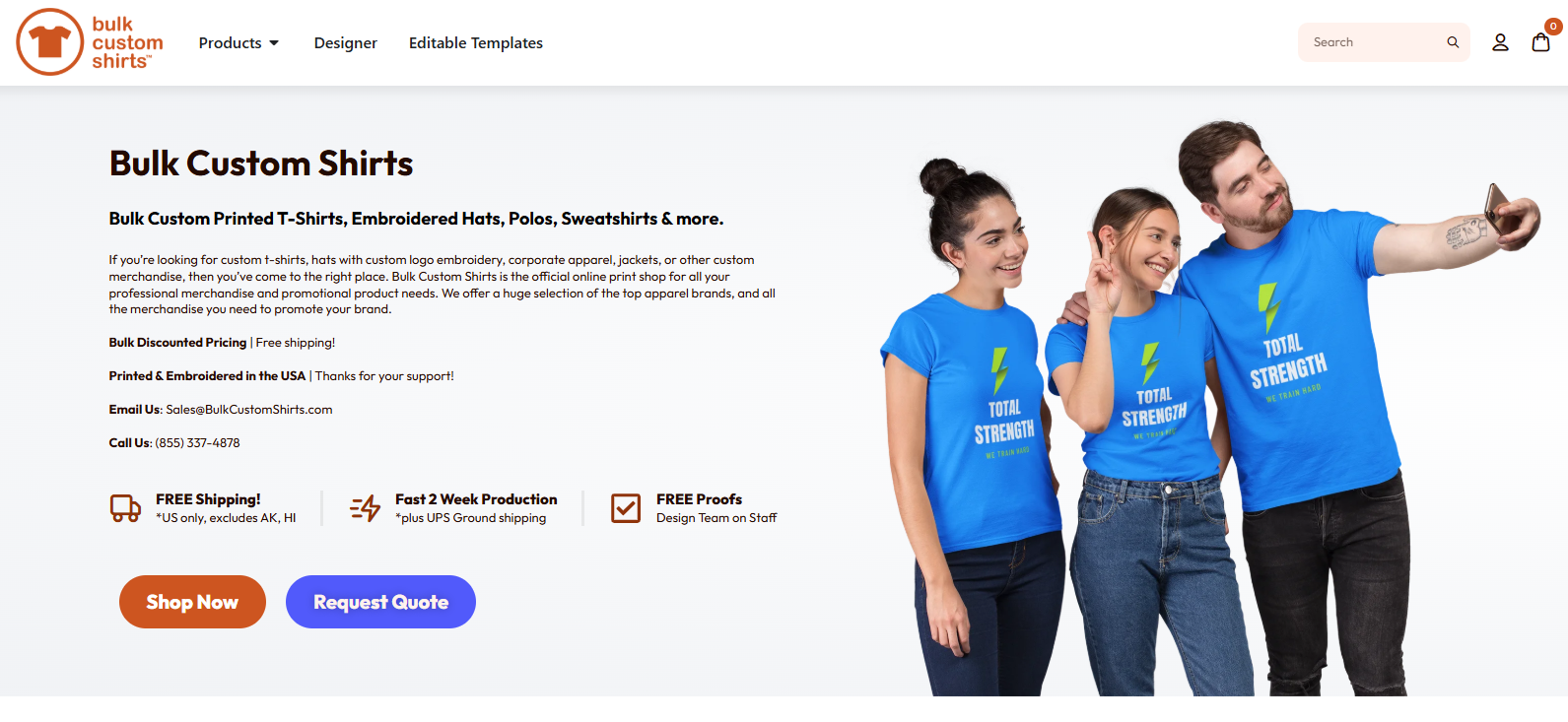

Sumissura merges tech and tradition for tailored elegance across genders.1. Bulk Custom Shirts - Best for Affordable Bulk Orders

Website: https://bulkcustomshirts.com/

Bulk Custom Shirts offers cost-effective t-shirt printing for orders of 50+ shirts, with strong value.

Pros:

· Low bulk prices.

· Free 1-2 week delivery.

· 7-day customer support.

Cons:

· 48+ shirt minimum.

Summary:

A budget-friendly pick for businesses or events needing large quantities.1. Steve Apparel - Best for Custom Apparel Manufacturing

Website: https://steveapparel.com/

Steve Apparel, a US-based manufacturer, provides high-quality custom clothing with low MOQs and extensive design support.

Pros:

· Low MOQ (50 pieces).

· Private label and embroidery options.

· Handles design to packaging.

Cons:

· No returns on custom products.

Summary:

Steve Apparel is a reliable choice for brands needing end-to-end manufacturing solutions.1. Sotela - Best for Ethical Slow Fashion

Website: https://market45.co/brands/sotela/

Sotela crafts MTO women’s apparel in LA with organic materials and nontoxic dyes, emphasizing slow fashion.

Pros:

· Inclusive sizing (up to 10).

· 100% recycled packaging.

· Breathable, natural fabrics.

Cons:

· Extra shipping fees possible.

Summary:

Sotela appeals to eco-conscious brands with ethical, versatile designs.1. Broken Arrow - Best for Easy Online Design

Website: https://www.brokenarrowwear.com/

Broken Arrow’s user-friendly online designer and vast clipart library simplify custom apparel creation.

Pros:

· Free delivery.

· Fast turnaround.

· 24/7 ordering.

Cons:

· Customer service weekday-only.

Summary:

Great for DIY designers needing quick, accessible custom tees.1. Billoomi Fashion - Best for Private Label Solutions

Website: https://billoomifashion.com/

Billoomi Fashion, based in India, offers comprehensive private label services for global startups.

Pros:

· Small order support.

· High-quality apparel for all ages.

· Design confidentiality.

Cons:

· Small orders may cost more.

Summary:

A solid option for brands building private label collections with global reach.1. KidsBlanks by Zoe - Best for Children’s Custom Apparel

Website: https://www.kidsblanks.com/

KidsBlanks by Zoe specializes in high-quality blank garments for babies and kids, with a sustainable twist.

Pros:

· Variety of colors and sizes.

· Eco-friendly manufacturing.

· Responsive customer service.

Cons:

· Limited to children’s clothing.

Summary:

A niche leader for businesses targeting the children’s apparel market.Key Factors in Selecting a Custom Clothing Manufacturer

The right custom apparel producer can make a significant impact towards your brand's success. This are a few key things to consider in selecting your contractor:

· Research and Online Platforms: Use sites like Maker's Row or Alibaba to search for a manufacturer who will meet your needs. These sites offer complete profiles, and you can view different services provided, price, and past projects to compare.

· Experience and Reputation: Opt for manufacturers with a solid history of producing high-quality garments. Review customer feedback, testimonials, and portfolios to assess their expertise.

· Communication and Transparency: Clear, consistent communication is essential during production. Choose a manufacturer that’s responsive and offers transparent updates on timelines, costs, and progress.

· Samples and Quality Control: Purchase samples to quality test and ensure fit before high-volume production. Select manufacturers that have good quality control to ensure the end product meets your expectations.

Conclusion

In 2025, the custom apparel landscape offers a wealth of options. This list of top 10 custom clothing suppliers highlights the diversity available—whether you need speed, eco-friendly designs, or niche expertise. Leading the pack, Kutetailor sets the standard with its unparalleled personalization and quality, offering a tailored experience that can elevate any brand or project. Assess your priorities against these standout options, and take your apparel vision to new heights this year!

MORE 2025-03-31 -

Summer Suit Fabrics: The Best Materials to Stay Cool in Hot Weather

Summer Suit Fabrics: The Best Materials to Stay Cool in Hot WeatherSummer comes with heat, color, and a packed social calendar—garden weddings, business meetings during hot weather, or garden parties with little shade. As Charles Dickens once called it, the “prime and vigour of the year” demands we look sharp despite rising temperatures. For gentlemen everywhere, it is all about finding a suit that meets decorum without sacrificing comfort. The secret? It all comes down to the fabric you choose.

In this blog, we’ll explore the best summer suit fabrics, from timeless classics to modern blends. Let's begin on how you can beat the heat without sacrificing style.

The Best Summer Suit Fabrics: A Complete Rundown

Here’s a detailed look at the top fabrics for summer suits, drawn from expert insights and tailored for hot weather. Each offers unique benefits, so you can pick the one that suits your style and setting.

Linen

Linen is almost a synonym for summer—and deservedly so. Made up of natural flax fibers, its open, loose weave allows excellent ventilation, letting hot air out while cool air moves in. It's light, airy, and moisture-wicking by nature, so it rapidly draws sweat away to keep you dry and at ease, even on warm days. Linen's durability and sustainability add to its appeal, making it the go-to of green-conscious dresser.

What is special about linen is its timeless appearance. Wrinkles in the fabric give a relaxed, laid-back look—perfect for semi-formal occasions like summer weddings, and especially beach weddings. If you prefer a more edgy look, linen blended with other fibers (like cotton or wool) reduce creasing while still providing that cool, airy feel. Pair it with an open-neck shirt for maximum ventilation, and you have a custom smart casual suit that looks fantastic too.

Cotton

Cotton is a world favourite for good reason: it's light, durable, and super comfy. As a very breathable material, it promotes airflow by allowing air to circulate around your body, and its absorbency wicks sweat away from the skin to make you feel fresh. Additionally, cotton suits come in twill or poplin weaves and in many textures and weights to fit most summer events.

Compared to linen, cotton holds sharper lines, delivering a neater, smarter finish that lasts all day—ideal for commuting to the office or enduring long events. Add a bit of stretch to the blend, and you get a suit that moves with you, enhancing comfort and longevity. Whether it’s a casual gathering or a professional setting, cotton brings refinement and ease to your summer wardrobe.

Seersucker

Seersucker stands out with its puckered texture. Rooted in cotton, this fabric gets its name from the Persian words for “milk” (smooth strips) and “sugar” (gritty texture). The puckering lifts the fabric off your skin, promoting airflow to keep you cool on the hottest days.

Traditionally, seersucker suits come in relaxed fits and bold colors. For a modern twist, opt for a slim-fit, neutral version—pair it with an open-collared shirt or even a classic tee and trainers for versatile wearability. A summer staple combining style and practicality.

Lightweight Wool

Wool does not necessarily holler "summer," but light versions like fresco fabric or tropical wool are designed for warm weather. Constructed of loose, finer weaves, these fabrics retain less heat and humidity and are surprisingly breathable. Modern wool blends—mixed with silk, linen, or cotton—provide wool's crisp look with the cool feel of natural fibers, perfect for custom formal wear dress events.

Also, lightweight wool is naturally wrinkle-resistant, so your suit stays crisp from day to night. For extra breathability, choose a partially lined jacket, which cuts down on layers without compromising shape. This fabric proves wool isn't just for winter—it's an elegant choice for summer sophistication.

Chambray

Chambray may be less well-known, but it's a summer winner. This light, plain-woven cotton textile is breathable and absorbent, staying cool and fresh throughout the day. Similar to cotton, it provides a calm yet relaxed look—think easy chic for garden parties or relaxed summer soirees. Its simplicity is a plus for those who desire comfort without drama.

Silk-Linen Blends

For a touch of glamour, silk-linen blends are unbeatable. Combining linen's breathability with silk's sweat-wicking quality, this fabric makes you comfortable and dry on warm, muggy nights. The natural sheen adds luxury and sophistication, ideal for a summer night or formal evening out. Navy blue suits in this blend are especially dramatic—pair them with a crisp shirt for a dramatic, sleek look that demands attention.

Tweed

Tweed might conjure images of country estates, but lightweight summer versions flip the script. Woven from wool, it offers unexpected breathability when cut in fresher colors and modern profiles. Paired with the right accessories, tweed strikes a balance between classic and contemporary, making it a trans-seasonal option you’ll wear year-round.

Flannel

Flannel isn’t just for cold months. Lightweight flannel suits adapt to summer heat by letting body heat escape while resisting creases. Opt for brighter or pastel shades to lean casual—perfect for relaxed weddings or travel. For a smarter look, a summer-weight double-breasted flannel suit blends dressed-up style with lighter comfort.

Nylon

Nylon brings a contemporary edge to summer suits. Known for durability and resistance to wrinkles and shrinking, it’s woven into lightweight fabrics that suit warm weather. Nylon is blended with spandex for flexibility and moisture-wicking properties, making it a practical choice for active days or humid climates.

Enhancing Comfort: Colors, Patterns, and Construction

Fabric is not the only thing—construction, patterns, and colors play a big role in staying cool and looking good.

Best Colors for Summer Suit Fabrics

Light colors are a summer must-have. Colors like light grey, beige, sky blue, and soft pink don't just look fresh—they reflect the heat of the sun, remaining cooler in its presence. Light grey is versatile, pairing with any shirt. Beige exudes a classic summer vibe, perfect for outdoor events. Sky blue adds a refreshing pop, while soft pink brings playful flair. These hues work worldwide, from tropical beaches to urban rooftops.

Patterns to Dress Up Summer Fabrics

Patterns add personality to your suit. Checks (glen or windowpane) offer sophistication, especially on light backgrounds. Vertical stripes—pinstripes or seersucker’s own—elongate your silhouette for a slimming effect. Houndstooth, in lighter weaves, adapts to summer, while floral or geometric patterns make bold statements for special occasions. Balance them with a solid shirt to keep the focus on the fabric.

Construction Features for Hot Weather

A suit’s construction can make or break its summer performance. Unlined or partially lined jackets (lining limited to sleeves or upper back) maximize breathability by reducing layers. Minimal or no shoulder padding creates a relaxed silhouette and improves airflow. Open weaves and hand-stitched seams enhance ventilation, letting air move freely and moisture evaporate. Single-breasted styles, easily unbuttoned, offer quick relief from heat—ideal for any climate.

Choosing Your Ideal Summer Suit Fabric

From linen to nylon, the best summer suit fabrics are those that keep you cool and refined, no matter how hot it gets. Linen and cotton excel in breathability, lightweight wool and seersucker offer structure, while blends like silk-linen or nylon bring a touch of flair.

If you’re unsure which fabric suits your needs, reach out to Kutetailor or sign up for our made-to-measure suits online platform. You’ll find a wealth of options and expert advice to help you stay stylish and comfortable all summer long.

Answering Your Questions About Summer Suit Fabrics

Got questions? Here's what you need to know about selecting the best suit fabric for hot weather.

What Is the Best Suit Material for Hot Weather?

Breathability is determined by construction, weave, and fibre. The front-runner is linen with its open weave and drying ability, seconded by cotton for air ventilation and water absorption. Choose fabrics of less than 270 grams per meter—lighter, more airflow, and you keep cool in heat.

Which Fabric Suits Summer Weddings Best?

For weddings, it’s about style and comfort. Lightweight wool offers versatility, structure, and ventilation, making it ideal for formal days that stretch into evening. Linen shines for casual or beach weddings, its relaxed wrinkles fitting the vibe perfectly. Both keep you cool without compromising your look—choose based on the dress code.

How Do Fabrics Differ in Summer Performance?

Each fabric has its strengths. Linen wrinkles but breathes like no other. Cotton stays sharp and absorbs sweat. Seersucker resists creases with its texture. Lightweight wool holds shape, while chambray keeps it casual. Silk-linen adds sheen, tweed brings uniqueness, flannel adapts, and nylon flexes. Your choice depends on the occasion and how much upkeep you’re willing to handle.

MORE 2025-03-31 -

Smart Casual Dress Code: The Ultimate Guide to Stylish, Modern Office Attire

Smart Casual Dress Code: The Ultimate Guide to Stylish, Modern Office AttireIn today’s evolving workplace, dressing appropriately doesn’t mean sacrificing comfort or style. Enter smart casual—a dress code that blends professional polish with fashionable ease, making it a go-to choice for modern offices worldwide. Whether you’re heading to a startup meeting, a networking event, or a team outing, smart casual offers the perfect balance of sophistication and individuality. But what is it, and how do you get it right? This ultimate guide gathers everything you need to know about fashion for a smart casual look, including options from custom clothing manufacturers that can tailor your wardrobe to perfection.

What Is Smart Casual? A Modern Dress Code Explained

Smart casual is a style forward, office-inspired look that mingles timeless basics with style-driven pieces. Sleek, sophisticated dressing that's less dressy than straight-up business attire, yet still projects expertise and taste. Picture top-notch materials, streamlined silhouettes, and simple accessories—all wrapped up in an air that's earthy but elegant.

The term “smart casual” dates back to 1924, but it truly took off with Silicon Valley’s tech boom (cue the iconic turtlenecks and black jeans) and gained momentum during the Zoom era of remote work. Today, it’s a workplace standard, reflecting a shift toward flexibility and work-life integration. A pre-pandemic Randstad survey found that 33% of employees would quit over a strict dress code, while a 2023 Adzuna study of over 1 million UK job ads revealed 79.9% now mention relaxed attire—proof that smart casual is here to stay.

When and Where to Wear Smart Casual

Smart casual excels in fast-paced, innovative fields such as media, advertising, IT, fashion, and startups, where uniqueness is valued. It's also seeping into more conventional industries for in-house meetings, business casual lunches, or networking sessions. Outside the nine-to-five, it's perfect for company holiday parties, team-building activities, or any event where custom formal wear might be too much, but jeans-and-a-tee is too relaxed.

All that aside, context matters. A record label might welcome bold jumpsuits, while an accounting firm may prefer subtle tweaks to classic attire. Always check your company’s dress code or event invitations for guidance.

Smart Casual vs. Business Casual vs. Casual: Key Differences

Smart Casual vs. Business Casual

Business casual is closer to regular office wear—suit jackets without ties for men or skirts with sweaters for women. It's conservative, professional, and comfortable, usually worn in finance or for important meetings. Smart casual adds a little personality with fashion sense. Swap the suit for dark wash jeans and a blazer, or trade a silk scarf for a linen shawl. It's about adding personality through color, pattern, or on-trend cuts without losing professionalism.

Smart Casual vs. Casual

Casual is the most relaxed of the trio—think sweatpants and hoodies on Zoom calls or light jeans in a creative studio. It’s laid-back but can veer too informal for work. Smart casual steps it up, aiming for a low-key impression that still says “I’ve got it together.” In casual settings, bright colors and open-toe shoes might fly, but smart casual keeps it polished with refined basics.

Smart Casual No-Gos: What to Avoid

While smart casual provides latitude, there are missteps to avoid. To keep it sharp, steer clear of anything too sloppy, too sporty, revealing, or over-the-top. Here's what to avoid:

· Ripped or overly distressed jeans

· Tank tops, strappy tops, or muscle shirts

· Sweatshirts, hoodies, or athletic clothing

· Shorts or mini skirts

· T-shirts with bold graphics

· Flip-flops, sandals, or Crocs

· Flashy accessories or head-to-toe brights

· Unkempt hair, dirty nails, or a generally disheveled vibe

Smart Casual code: Remain neat, professional, and understated—no matter how informal the "casual" becomes.

Smart Casual for Women: Tips, Inspiration

For women, smart casual is a playground of style. Here’s how to ace it with pieces like custom women's clothing designed to fit your unique shape and taste.

Clothing Options

· Tops: From crisp blouses to sweaters, cardigans, or even T-shirts—choose high-quality materials without boisterous prints.

· Bottoms: Smart trousers, skirts (knee-length or longer), or dark jeans work wonders. Wide-leg styles like culottes or Marlene trousers add trendy elegance.

· Dresses: Conservative cuts in chic fabrics are perfect—just avoid anything too short or sheer.

· Shoes: Loafers, ballet flats, or heels keep it classy; clean, sleek sneakers can work depending on your office.

Smart Casual for Men: Tips, Inspiration

Men can seamlessly shift from business casual to smart casual with a few tweaks, balancing professionalism with individuality. For a perfect fit, consider made to measure suits online that adapt to your style and body.

Clothing Options

· Jackets: A well-fitted blazer is a cornerstone—mix fabrics or colors with your trousers for flair.

· Tops: Go for plain shirts, subtle-pattern button-downs, luxe polos, or elegant sweaters.

· Bottoms: Classic trousers, chinos, or dark, clean jeans offer versatility.

· Shoes: Leather lace-ups, loafers, or Chelsea boots are safe bets; minimal sneakers work if pristine.

Why Smart Casual Works: Benefits and Trends

Smart casual isn’t just a dress code—it’s a modern way to navigate work and life with style. Its magic lies in its versatility: you can dial it up with a tailored blazer or down with crisp sneakers, all while showcasing who you are through thoughtful details—be it a pop of color, a luxe fabric, or a standout accessory. In today’s hybrid world, custom smart casual options bridge the gap between remote comfort and office polish, proving you don’t have to choose between looking good and feeling great. As workplaces evolve, smart casual remains a timeless ally—adaptable, confident, and effortlessly you. So, next time you’re dressing for that meeting or mixer, lean into the freedom it offers.

FAQ

What is not allowed in the smart casual dress code?

Anything excessively casual or sloppy is off limits—ripped jeans, hoodies, flip-flops, or graphic tees. Steer clear of sporty gear, tacky cuts, or overly showy accessories.

How to dress smart casual for females?

Pair a crisp blouse or sweater with tailored trousers, a skirt, or dark jeans. Add loafers, flats, or low heels, and keep fabrics luxe and cuts refined.

What is a smart casual dress code example?

Here are some common examples: For women: a white blouse, navy culottes, and loafers. For men: a blazer, plain shirt, dark jeans, and leather boots. Both are sharp, comfy, and effortlessly stylish.MORE 2025-03-31 -

The Ultimate Guide to Summer Wedding Suits for 2025

The Ultimate Guide to Summer Wedding Suits for 2025Summer weddings bring romance, sunshine, and a touch of magic—hot nights under the stars, flowers in bloom, and love in the air. Whether you’re the groom, bride, part of the wedding party, or a guest, your suit can make or break your day. The challenge? Staying cool and comfortable in the heat without sacrificing style. This guide gives 2025's best summer wedding suit ideas for everyone, from light-weight clothes to role-defining styles, so you're the life of the party around the world.

Key Factors to Consider Before Choosing Your Summer Suit

Before picking your suit, consider these universal essentials: fit, fabric, color, venue, and your role. A tailored fit ensures comfort, breathable fabrics like linen or cotton beat the heat, and light colors reflect summer vibes. The venue—beach, ballroom, or backyard—sets the formality, while your role (groom, guest, etc.) defines your standout level. Nail these, and you’re set for a global summer wedding win with help from custom clothing manufacturers who can craft the perfect fit for any occasion.

Best Fabrics for Summer Wedding Suits

Fabric is your foundation. This is what works best in 2025's heat.

Lightweight Wool and Blends

Light wool or wool-linen blends offer structure without stifling—ideal for any role needing polish with breathability.

Cotton: The Breathable Classic

Cotton’s light, airy nature and affordability make it a classic option for informal weddings or budget-conscious wedding parties around the world.

Linen: The Summer Staple

Linen's sweat-wicking, relaxed charm is perfect for hot weather.

Seersucker and Silk: Special Picks

Seersucker’s wrinkled coolness is ideal for fun styles, while silk adds luxury for standout pieces like jackets or ties.

Types of Suits for Summer Weddings

Your suit's style does make the difference. Here’s how to pick the right one for summer 2025.

Single-Breasted Suits

The single-breasted suit, traditional in two-piece or three-piece with vest, is always a safe bet. Ditch the jacket later for a breezy vest-only look that’s still polished. It's dressy enough for any wedding, from casual to semi-formal.

Double-Breasted Suits

Want to stand out? A double-breasted suit adds a dressy edge. Keep it lightweight and unlined to avoid overheating, and you’ve got a bold groom’s look or a confident guest outfit for an indoor evening affair.

Tuxedos for Summer

Tuxedos are not just for cold weather! Summer tuxedos are available now at lighter fabrics (like ivory or pale gray) to dress formal for a warm reception of stars. Reserve them for more formal events—perfect for a groom at an opulent affair or a black-tie guest seeking custom formal wear.

Unstructured Suits

Unstructured suits skip heavy padding and linings, letting air flow freely. They’re smart yet relaxed, perfect for beach weddings where comfort is paramount. Combine with a fitted cut to prevent sloppy appearance.

The Perfect Summer Suit Color

Color can make or break your summer wedding vibe. Here’s how to get it right.

Light and Neutral Tones

Light grays, beiges, and creams reflect heat and exude timeless elegance. They’re universally flattering and suit daytime ceremonies, remaining cool and classic.

Pastels and Earthy Colors

If you're after something fresh, try pastels like sky blue, blush pink, or sage green. Earthy shades—khaki, muted tan—add warmth without heaviness. These shades are trendy in 2025 and ideal for adventurous grooms or style-conscious guests.

Bold Colors for Standout Looks

Bold and daring? Opt for bright purples, greens, or a pale red. Ideal for a casual affair or night wedding, bold colors project your personality—just coordinate with the wedding theme to avoid clashing.

Summer Wedding Suits for Every Role

Your role shapes your suit. Here’s tailored advice for 2025.

Summer Wedding Suits for the Groom

Grooms require balance—stand out without overwhelming the wedding atmosphere. Opt for a light gray linen three-piece suit for versatility: jacket on for the ceremony, vest-only for dancing. Bold blues or an ivory tuxedo work for evening flair. Coordinate with your partner’s attire, and choose lightweight wool or cotton for comfort all day long.

Summer Wedding Suits for the Bride

Suits are a chic alternative to gowns. Go for fitted white linen pantsuit for classic bridal look, or pale sage green outfit for modern twist. Silk blends add an air of sophistication, and loose styles keep it cool. Pair with show-stopping earrings to turn heads, perfect for a world spotlight with custom women's clothing.

Summer Wedding Suits for Groomsmen

Groomsmen should match the groom's appearance without overdoing it. Beige or sand-colored cotton suits keep the group looking crisp and cool. Slim-fit linen in muted colors like khaki goes with any color scheme. Substitute jackets with vests for casual venues—sophisticated and carefree worldwide.

Summer Wedding Suits for Bridesmaids

Swap dresses for suits with soft pastel sets—think lavender or mint green linen. Lightweight chiffon or crepe ensures comfort, making this a trendy 2025 choice for bridal parties everywhere.

Summer Wedding Suits for Male Guests

Guests have flexibility—light gray or soft blue cotton suits hit the sweet spot between style and ease. Avoid tuxedos unless it’s black-tie; opt for unstructured linen in beige for daytime. Stick to the dress code, but let your personality peek through with a bold shirt.

Summer Wedding Suits for Female Guests

Female guests can rock sage green linen jumpsuits or tailored blazer-trouser combos in soft neutrals. Relaxed fits keep you chic and cool—add minimal accessories like a clutch for elegance. Perfect for honoring the couple without stealing the show.

Accessorizing Your Summer Wedding Suit

Accessories tie everything together—you want to wear them light and smart.

Ties, Vests, and Suspenders

A lightweight tie in a pastel shade adds flair; skip it for suspenders in casual settings with custom smart casual options. Vests offer versatility—wear them solo when the jacket comes off, keeping you dapper on the dance floor.

Shoes and Socks

Breathable loafers or suede oxfords beat heavy boots. Pair with moisture-wicking socks in subtle tones—or quirky patterns for fun, informal vibes.

Hats, Sunglasses, and More

A straw hat or stylish sunglasses protect you outdoors while adding charm. Keep frames light and avoid sporty styles for a wedding-ready finish.

7 Rules to Ace Your Summer Wedding Look

Follow these seven golden rules to nail your 2025 summer wedding style.

Rule 1: Prioritize Breathable Fabrics

Stick to linen, cotton, or light wool—say no to heavy flannel or polyester.

Rule 2: Opt for Light Colors

Choose neutrals or pastels to reflect heat and match the season’s vibe.

Rule 3: Add a Vest for Versatility

A vest keeps you polished when the jacket’s off—perfect for dancing.

Rule 4: Nail the Perfect Fit

Tailoring ensures comfort and confidence, no matter your body type.

Rule 5: Customize for Comfort

Go bespoke for lightweight construction—half-lined or unlined jackets beat the heat.

Rule 6: Choose Venue-Appropriate Styles

Match formality to the setting—relaxed for beaches, structured for ballrooms.

Rule 7: Accessorize Smartly

Pick seasonal extras like silk ties or loafers to elevate your look without overheating.

Our Favorite Summer Wedding Suit Trends for 2025

Need inspiration? Here are five standout options for 2025.

The Classic Light Gray Suit

A light gray linen or wool blend is cool, versatile, and reusable—perfect for grooms or guests.

The Bold Blue Suit

A saturated blue cotton suit brings elegance with a summery twist, ideal for daytime or evening.

The Antique White Beach Look

Antique white linen screams beach chic—great for grooms or bold guests, with a colorful accent.

The Modern Summer Tuxedo

A soft gray or ivory tuxedo blends formality and warmth, a groom’s evening standout.

The Seersucker Southern Charm

Seersucker’s subtle stripes add cheer and comfort—a quirky pick for any role.

Conclusion: Shine at Your Summer Wedding

Wherever you are in the world, a summer wedding is your chance to shine. Start with breathable fabrics like linen or cotton, pick a light or bold color that suits your style, and tailor it to perfection. Match the venue, add smart accessories, and follow our seven rules to ace your look. Whether you’re saying “I do” or cheering from the sidelines, plan ahead, stay cool, and let your suit make 2025’s summer weddings unforgettable. Your perfect suit awaits!

FAQ

What color suit is best for a summer wedding?

Light and neutral colors like grays, beiges, and creams are some of the best choices—they reflect the sun and keep you cool at daytime events. For something fresh, pastels like sky blue or sage green are trendy, while bold colors like purple fit casual or evening weddings. Match the location and theme for the perfect atmosphere.

What is the best material for summer wedding suits?

Linen reigns supreme for its sweat-wicking, lightweight charm—ideal for hot weather. Cotton is a close second, offering breathability and affordability. Lightweight wool blends work for polish without the weight, while seersucker and silk add unique flair. Choose based on comfort and your role.

What is the fashion trend for summer wedding suits in 2025?

In 2025, expect soft pastels (lavender, mint) and earthy tones (khaki, sage) to dominate, paired with unstructured, breezy fits. Vests are big for versatility, and sustainable fabrics like organic cotton or linen blends reflect a growing eco-conscious vibe. Bold accessorizing—think silk ties or loafers—rounds out the look.

MORE 2025-03-26 -

Wedding Dress Codes Unveiled: Your Global Guide to Guest Attire and Planning

Wedding Dress Codes Unveiled: Your Global Guide to Guest Attire and PlanningWeddings are a universal celebration of love, but figuring out what to wear—or what to ask your guests to wear—can feel like cracking a secret code. Whether you’re a guest puzzling over "Black Tie Optional" or a couple planning a dreamy beach ceremony in Australia, a chic castle wedding in Scotland, or a festive backyard bash in the States, this guide has you covered. We’ll break down the world’s most common wedding dress codes, show you how to choose the perfect one for your big day, and even help you word it just right. Let’s dive in and make dressing for the occasion as joyful as the celebration itself.

The Ultimate List of Wedding Dress Codes

From the grandeur of a royal ballroom to the chill of a seaside vow exchange, here are 12 wedding dress codes you’ll encounter globally, ranked from most formal to most relaxed. Each comes with clear attire tips to help guests shine and couples set expectations.

White Tie Attire

White Tie is the pinnacle of formality—think state dinners, royal galas, or ultra-luxe weddings. It’s rare, but if you’re invited to one, it’s your chance to channel red-carpet glamour. Women should wear floor-length ball gowns, A-line dresses, or sheaths, paired with heels, fine jewelry, and perhaps elbow-length gloves. Men need a black tailcoat tuxedo, white vest, white bow tie, and patent leather shoes—consider sourcing from custom clothing manufacturers for a perfect fit. This is all-out elegance, no shortcuts allowed.

Black Tie Attire

A step down but still elegant, Black Tie is a go-to for evening weddings around the world. Look for it in upscale venues, such as city hotels or grand estates. For men, the tuxedo is paired with a black bow tie (or long tie), white shirt, and optional vest or cummerbund. Women wear floor-length gowns in rich fabrics like silk or satin, paired with heels and sparkling accessories: formal, but with a little celebration.

Black Tie Optional

Black Tie Optional offers flexibility and keeps things dressed up. Used for semi-formal evening events, the dress code gives the male guest the choice of a tuxedo or dark suit with tie and the female guest a floor-length gown or fashionable knee-length cocktail dress. This is best for the guests to avoid overdressing or underdressing in comparison with the tuxedo crowd.

Creative Black Tie

A fun version of Black Tie, this dress code brings personality to formality. Great for adventurous couples who like to make a fashion statement, it demands tuxedos with interesting patterns—velvet or plaid for men, and sequined evening gowns or cocktail dresses with some flair for women, possibly tailored by custom formal wear specialists. Add touches of whimsy in accessories, such as a rainbow-colored bow tie or statement earrings—it's formal, yet not too serious.

Cocktail Attire

Cocktail Dress is both dressy and casual and is a common sight at parties in the evening. Men dress in a tailored suit-tie optional-and women in knee-length or midi dresses: little black dresses or party-bright separates. Dressy enough for a party, but not as formal as Black Tie, it's a worldwide crowd-pleaser.

Semi-Formal Attire

Semi-Formal is almost the same as Cocktail but is a bit more casual, especially for daytime weddings. For men, a dress shirt with a jacket and slacks, and tie optional; for women, midi dresses, wrap dresses, or elegant jumpsuits are great. Darker colors can be used during the evening while lighter hues for the sunny ceremonies.

Festive Attire

Festive Attire is a newer, lighter version of code that is creative within a semi-formal framework. Picture cocktail-style clothing with a bold spin—patterned suits or colorful ties for men, and fun dresses with playful accessories for women. It's perfect for holiday weddings or couples who want their guests to let loose and dance.

Garden Party Attire

For higher-end outdoor weddings, Garden Party Attire is a mix of elegance and practicality. Ladies sport upscale spring dresses (midi or tea-length) with wedges or flats for walking on grass—check out custom women's clothing for unique designs—while gentlemen opt for light suits or blazers with slacks. Florals and pastels are appropriate for the atmosphere, which makes it well-suited for rustic or country venues.

Dressy Casual Attire

Dressy Casual is a business casual with a celebratory twist. Pictorially, it sounds like polished comfort: women in a sundress or nice separates with flat shoes; men in button-down shirts with chinos or a blazer without a tie, easily sourced from custom smart casual providers. It's comfortable enough for a daytime event where style meets comfort.

Casual Attire

Casual doesn't mean sloppy-it's still a wedding! Typical for relaxed locations such as backyards or beaches, women wear sundresses and sandals, and men wear polo shirts or button-downs and khakis. Avoid jeans and flip-flops unless the couple specifically permits it.

Beach or Destination Attire

Beach or Destination Attire prioritizes lightweight fabrics for warm climates. Women choose flowy maxi dresses or sundresses with sandals (skip stilettos!), while men wear linen shirts and pants or even a guayabera shirt for a tropical twist. Breathability is key, whether it’s a Hawaiian shore or a Caribbean resort.

Themed Attire

Themed Attire lets couples take guests on a journey—think 1920s Gatsby glam or a Halloween costume party. Outfits depend on the theme (flapper dresses, cowboy boots), so check the invite or website for clues. It’s a chance to get creative, formal or casual, as the couple desires.

Planning the Perfect Dress Code for Your Wedding

If you’re the one tying the knot, choosing a dress code shapes your wedding’s vibe. Here’s how to pick one that reflects your style and keeps guests happy, no matter where in the world you’re celebrating.

Match Your Vision and Venue

Your attire code must reflect your place and theme. Black Tie cries out for a castle in Ireland, while a California vineyard may invite Garden Party or Cocktail. Align it with your vision to set the right mood.

Time of Day and Season

Timing matters. Night weddings are formal (Black Tie, Cocktail), and day ones Semi-Formal or Casual. Season comes into play as well—light linens for a July beach wedding in Australia, or more substantial colors for a winter wedding in Canada. Coordinate the dress code with clock and calendar.

Guest Comfort and Style

Your guests should feel great, not fidgety. A White Tie code might dazzle but exhaust attendees at a long outdoor event. Opt for something stylish yet practical—like Dressy Casual for a summer day—so everyone enjoys the party from start to finish.

Communicating Your Dress Code: Wording Tips and Examples

After deciding on a dress code, good communication gets guests prepared. Here’s how to share it effectively, plus wording ideas for every style.

Where and How to Post It

Include your dress code on the invite (bottom corner is a great spot) for a brief heads-up. For specifics—such as "no heels on the beach"—post a note on your wedding website. Keep it brief and courteous, following your invite's tone.

Wording Examples for Every Dress Code

Need inspiration? Here are concise, global-friendly examples:

· White Tie: “White Tie Elegance: Dress in your finest formalwear.”

· Black Tie: “Black Tie Affair: It’s a fancy night—tuxedos and long dresses, please.”

· Black Tie Optional: “Black Tie Optional: Formal attire encouraged.”

· Creative Black Tie: “Creative Black Tie: Add flair to your formal look.”

· Cocktail: “Cocktail Chic: Dress up for a stylish evening.”

· Semi-Formal: “Semi-Formal Daytime: Smart and elegant, please.”

· Festive: “Festive Fun: We love color—wear something fun and semi-dressy!”

· Garden Party: “Garden Party Grace: Outdoor-friendly elegance.”

· Dressy Casual: “Dressy Casual Comfort: Polished yet relaxed.”

· Casual: “Casual Vibes: Keep it comfy and stylish.”

· Beach or Destination: “Beach Bliss: Light, breezy attire.”

· Themed: “1920s Glam: Step back in time with us!”

Handling Unique or No Dress Code Scenarios

For quirky codes like “Tropical Formal,” explain it on your website (e.g., “Think linen suits and flowy dresses”). No dress code? Suggest “Cocktail or Semi-Formal” as a safe bet, and invite questions to avoid guesswork.

Global Wedding Guest Tips: Dos and Don’ts

Wherever you’re celebrating, these tips ensure you’re the guest everyone admires—not the one they whisper about.

What to Wear (Dos)

Follow the dress code, but tweak for the setting—dark suits for evening city weddings, airy fabrics for beach days. Check the venue (grass? sand?) and local weather to nail your look. If in doubt, overdress slightly—it’s a wedding, after all.

What to Avoid (Don’ts)

Skip white (leave that to the bride), overly revealing outfits, or anything too casual (jeans, sneakers) unless specified. Avoid clashing with the bridal party—ask about their colors if unsure. Comfort matters, so ditch painful shoes you can’t dance in.

Adapting to Local Cultures

Weddings vary around the world. For instance, in India, bright colors may be encouraged, while a Scottish estate may go for understated sophistication. Research or ask the couple about cultural norms to understand how to balance respect with style—especially for destination events.

Final Say

Whether you’re a guest decoding an invite or a couple crafting your dream day, the right dress code ties everything together. From White Tie splendor to Beach Casual ease, it’s about feeling fabulous and fitting the moment. So pick your attire—or your wording—with confidence, and get ready to celebrate love, wherever the world takes you!

FAQ

What dress code are weddings usually?

Most weddings fall between Cocktail and Semi-Formal—popular for their balance of elegance and ease. Black Tie is common for upscale evening events, while Casual or Beach Attire suits relaxed or outdoor settings. It depends on the couple’s vibe, venue, and time of day.

How do I tell guests their wedding dress code?

Add it to your invitation—bottom corner works best—like “Cocktail Attire” or “Beach Casual.” For clarity, include details on your wedding website, such as “Suits or dresses, no heels on the sand!” Keep it friendly and simple, and welcome questions.

What is the smart dress code for a wedding?

“Smart” typically aligns with Semi-Formal or Dressy Casual. Men wear a jacket, slacks, and optional tie; women choose midi dresses or chic jumpsuits. It’s polished yet comfortable—perfect for daytime or less formal evening weddings.

What is not appropriate to wear as a wedding guest?

Avoid white (it’s the bride’s spotlight), anything too revealing, or overly casual items like jeans, flip-flops, or sneakers unless specified. Steer clear of matching the bridal party’s colors—check with the couple if unsure.

What is the best dress code for attending a wedding?

There’s no one-size-fits-all, but Cocktail Attire is a versatile favorite—suits for men, knee-length dresses for women. It’s dressy enough to honor the occasion but not as rigid as Black Tie, making it a safe, stylish choice when in doubt.

MORE 2025-03-20 -

What Is Formal Attire for a Wedding?

What Is Formal Attire for a Wedding?Receiving a wedding invitation often sparks a flurry of excitement—and a pinch of nervousness. One of the first things on your mind is, "What do I wear?" When the invitation requests you to dress formally, you can't help but wonder exactly what that means. Whether it’s your first black-tie optional event or a church wedding with a sophisticated vibe, understanding formal wedding attire is key to showing up as a perfectly dressed guest. It's not so much about looking fashionable—it's about respecting the occasion and feeling secure in your attire.

In this comprehensive guide, we’ll break down everything you need to know about formal wedding attire. Let's begin and make you look perfect on the wedding day.

Key Characteristics of Formal Wedding Attire

Formal wedding attire is often described as a step above semi-formal or cocktail dress codes but just below the strict elegance of a black-tie affair. It’s a dress code that calls for sophistication, polished outfits, and a refined sense of style, while still leaving room for personal touches. The main characteristics to be noted are the following:

· Luxury Fabrics: Opt for upscale fabrics like worsted wools, mixed noble fibers (cashmere, alpaca, silk), lace, satin, organza, taffeta, or structured cotton and linen mixtures for hot climates. These fabrics elevate the look beyond casual or semi-formal options.

· Deep and Classic Colors: Darker shades like navy, charcoal grey, black, or deep shades like burgundy and hunter green would be most appropriate for formal events, although lighter hues like pale blues or earth tones can be applied depending on the venue and time of year.

· Custom Fit: Whether a suit, tuxedo, gown, or pantsuit, the fit counts. Wedding wear that's formal must be clean and crisp cut, molding to your form without feeling restricting. For a truly tailored experience, consider working with custom clothing manufacturers to ensure your attire fits perfectly.

· Elevated Accessories: The accessories make formal wedding attire stand out. In men's cases, these are ties, bow ties, cufflinks, or pocket squares; for women, think about jewelry, stilettos, and elegant clutches.

Men's Formal Wedding Attire

When it comes to formal wedding attire for men, the dress code offers a balance of sophistication and flexibility. You’ll typically choose between a suit and a tuxedo, with options to elevate your look through fit, fabric, and accessories. Here’s a detailed breakdown:

Suits vs. Tuxedos

For a formal or black-tie optional wedding, men can opt for either a suit or a tuxedo. They're both fine, and the choice is usually one of personal taste or level of comfort with formality. A tuxedo is inherently polished and reserved for special events, making it a perfect fit for formal weddings—though steer clear of a white tuxedo, as it’s reserved for white-tie events or the couple themselves. If you choose a suit, stick primarily to darker, richer colors like black, charcoal grey, or navy, since they are seen as more elevated than their lighter-toned counterparts. Avoid extremely bright colors in order to maintain the formality and ensure your attire is consistent with the level of sophistication indicated in the dress code.

Single vs. Double-Breasted Suits

Your suit cut can offer a further kick of formality. Double-breasted and single-breasted suits are both ideal for wedding ceremonies. A double-breasted suit offers a slightly more formal, lesser-seen touch, getting the perfect equilibrium between cocktail dressing and black-tie level dress. It keeps your look distinguished from a tuxedo without compromising the dress code.

Three-Piece Suits

A three-piece suit—jacket, trousers, and vest—is a timeless choice that adds grace and formality to your appearance. A waistcoat under a single-breasted suit is one of the great classic styles which never goes out of fashion. Burgundy, dark blue, navy, or deep greys are excellent formal options. For a bespoke touch, explore custom formal wear to craft a three-piece suit that’s uniquely yours.

Shirts and Ties

A crisp dress shirt is non-negotiable, whether paired with a suit or tuxedo. For tuxedos, a classic tuxedo shirt or French cuff dress shirt works best. With suits, opt for a white dress shirt or one in a refined color or subtle pattern. Ties are a must for formal attire weddings—both bow ties and neckties are acceptable, though bow ties are traditionally reserved for black-tie events. If you’re wearing a suit, a bow tie can bring it closer to a tuxedo-level look.

Shoes and Accessories

Dress shoes are essential and must be as formal as your outfit. Black, brown, or burgundy leather (avoid patent or suede) is the best. Cufflinks, a silk pocket square, or suspenders (never a belt at formal events) are the addition. As a personality touch, employ patterned socks or a colored pocket square, depending on the event.

Patterns and Fabrics

Formal attire doesn’t have to mean solid colors only. A thin windowpane or small houndstooth check can work beautifully in formal settings. Fabrics should lean luxurious—think rich worsted wools, alpaca, silk, or cashmere blends for cooler weather.

Formal Wedding Attire for Women

For women, wedding formal wear provides a variety of dressed-to-the-nines possibilities that marry elegance with personality. From the floor-length gowns to more contemporary options, here's what to look for:

Dresses and Gowns

Dresses are the standard choice for wedding formal attire, floor-length dresses being the norm. Midi dresses or elevated cocktail dresses can work if they have rich details like embroidery, lace, ruffles, or silky fabrics. Satin, lace, organza, and taffeta are good fabrics to use in order to gain a luxurious look. Avoid cotton maxi dresses—these are better suited to casual or semi-formal gatherings.

Pantsuits and Jumpsuits

Not a dress person? A custom-designed women's pantsuit in a darker shade like burgundy or black is a stylish alternative that is just as formal. Loose or starched jumpsuits are also compliant, especially when paired with formal bling like heels and accessories. For a perfect fit, consider custom women’s clothing to tailor these modern designs to your style.

Tuxedos for Women

For the dramatic, red-carpet-style look, women can don a tuxedo. Classier than a pantsuit, the women's tuxedo is easily made over with accessories and has been a popular, chic choice for special events.

Shoes and Jewelry

Footwear should be elegant—think heels, polished loafers, or fancy flats. Strappy heels or sparkly shoes add a glamorous touch, while simple gold or diamond stud earrings, necklaces, or bracelets can elevate your look. If your dress is bold, keep jewelry simple; for a simpler gown, a sparkly earring or tassel earrings can add flair.

Formal Wedding Attire by Scenario

Formal wedding attire can vary depending on the setting, time of day, or specific dress code nuances. Here's how to alter your dress code for various occasions:

Black-Tie Optional Weddings

Black-tie optional weddings are nearly as formalized as black-tie affairs, but with a bit of latitude. Men may wear a tux or a very dark suit (navy or black) with a tie, and women will want to dress in a floor-length gown, a very fancy cocktail dress, or a glamorous pantsuit.

Church Weddings

For a church formal wedding, modesty is the rule. The shoulders of ladies should be covered and there should be no overly revealing or sexy attire—go for a lace short-sleeved tea-length wedding dress or floor-length wedding dress with shawl. A suit or dark-colored tuxedo is appropriate for men so long as the look is respectable and classic.

Beach Weddings

A formal beach wedding allows light-hued fabrics and a more casual hemline without sacrificing elegance. Women can dress in flowy gowns in pale or vibrant colors, silk or chiffon, and pair them with wedges, espadrilles, flats, or wide block heels to stroll on the sand. Men can choose a light-colored suit (e.g., pale blue) made of breathable fabric like linen-cotton blends, blending formal elegance with a custom smart casual twist for the relaxed setting. A light cover-up, like a pashmina, might be enough to warm you up if it gets cold.

Evening Weddings

Evening formal weddings call for all-out glamour. Women can go for deep-colored gowns with sequins, ruffles, or a subtle train—think a floral sleeved gown with pockets or a lace dress with intricate details. Men should lean toward darker tuxedos or suits (black or navy) with polished accessories like a bow tie or silk pocket square.

Seasonal Considerations for Formal Wedding Attire

Season may influence your color and fabric selection for formal wedding attire. This is what to wear during each season:

Spring and Summer Weddings

In warmer months, opt for lighter fabrics like pure cotton, linen-cotton blends, or silk for men, and chiffon, lace, or organza for women. However, avoid casual cotton dresses for women—this isn’t the time for them in a formal setting. A light grey linen-cotton suit for men or a pastel gown for women brings a touch of levity while remaining formal. Avoid heavier fabrics like velvet or taffeta, which can cause overheating. Colors like light blue, tan, or brighter blues work well, as do standout shades like pale purple, depending on the setting.

Fall and Winter Weddings

Cooler months call for richer fabrics and deeper tones. Men can choose pure wool blended with cashmere or alpaca for warmth and refinement, or wool-silk blends for a subtle sheen. Women can embrace velvet, satin, or taffeta gowns in earthy tones like burgundy, navy, brown, or hunter green. Long-sleeved dresses or one-shoulder gowns are appropriate, as are suede open-toe shoes or velvet pumps for a chic seasonal touch.

Accessories to Elevate Your Formal Wedding Look

Accessories are the last touches that can elevate your formal wedding wear to the next level. Here's accessorizing for men and women:

For Men

Start with a classic silk tie or a bow tie (though bow ties are best reserved for black-tie attire). In winter, wool flannel ties add texture and depth; in summer, opt for a cotton or linen blend tie. Cufflinks are essential for French cuffs—go for sterling silver studs or something more novel for personality. Suspenders in tonal shades (dark brown, navy) with leather buckles are a nice touch, and never wear a belt with formal attire. Add a silk pocket square or patterned socks for a subtle flair.

For Women

Leave the casual leather purses at home—opt for a small sequined clutch or sparkly handbag instead. Shoes should be dressy, like strappy Steven Madden heels or glittery flats. A light jacket or wrap, like a pashmina, can keep you warm at evening or beach weddings. For jewelry, keep it simple with gold hoops or diamond studs if your dress is bold, or go for fun tassel earrings to spruce up a simpler gown.

The Last on Formal Wedding Attire

It is important to know what formal wedding attire is, especially for any guest who wishes to honor the couple's wishes and feel comfortable at the event. This type of dress code requires a lot of elegance—think of it as tailored dresses, tuxedos, floor-length gowns, or stylish pantsuits—yet still leaving space for individuality. Whatever is your attraction—perhaps to a traditional navy three-piece suit, a stunning sequined dress, or a hip women's tuxedo—the trick is to make your ensemble elegant, well-fitted, and suitably occasioned.

Owing to the flexibility of formal attire, you can experiment with color, jewelry, and modern choices within the parameters of the dress code. Go for it—dress up, indulge in the elegance, and create a look that's uniquely yours for the event.

FAQs About Formal Wedding Attire

What does a guest wear to a formal wedding?

A guest at a formal wedding should wear polished, sophisticated attire that respects the dress code. For men, this means a dark suit (black, navy, or charcoal grey) or a tuxedo with a dress shirt, tie, and leather dress shoes. For women, options include a floor-length gown, an elevated midi or cocktail dress, or a tailored pantsuit, paired with heels or fancy flats and formal accessories like jewelry or a clutch.

What is formal attire for a wedding mean?

Formal attire for a wedding refers to a dress code that’s fancier than semi-formal or cocktail attire but not as strict as black-tie. It’s often similar to black-tie optional, requiring elevated outfits like tuxedos or dark suits for men and floor-length gowns, fancy dresses, or polished pantsuits for women. It emphasizes luxurious fabrics (silk, wool, satin), deep colors, and a tailored fit, with room for personal style.

Can a woman wear a short dress to a formal wedding?

A woman can wear a short dress to a formal wedding if it’s elevated enough—think a fancy cocktail dress with luxurious details like lace, embroidery, or satin. However, floor-length gowns or midi dresses are typically the safest and most traditional choices for formal attire. Avoid casual short dresses like cotton maxis, and ensure the overall look remains sophisticated with formal shoes and accessories.

What does a man wear to a formal wedding?

A man should wear a suit or tuxedo to a formal wedding. A dark-colored suit (black, charcoal grey, or navy) paired with a crisp dress shirt, tie (bow tie or necktie), and polished leather shoes (black or brown) is ideal. For a more elevated option, a tuxedo works perfectly, especially for black-tie optional events. Add accessories like cufflinks or a pocket square to complete the look.

What does formal wear for a wedding look like?

Formal wear for a wedding looks polished and elegant, balancing sophistication with individuality. For men, it’s a tailored dark suit or tuxedo with a dress shirt, tie, and dress shoes, possibly enhanced with a vest or suspenders. For women, it’s a floor-length gown, a fancy midi dress, or a sleek pantsuit in rich fabrics like silk or velvet, accessorized with heels, jewelry, and a clutch. The outfit should feel refined and occasion-appropriate, avoiding casual elements.

MORE 2025-03-20