-

Why Custom Clothing is Worth the Investment: Benefits, Quality & Long-Term Value

Why Custom Clothing is Worth the Investment: Benefits, Quality & Long-Term ValueIn today's fashion world, where quick turnarounds often equate to poor quality, custom-made clothing comes out to be an enduring solution. Whether you are running a fashion business or a small ready-to-wear shop, keep in mind that custom clothing isn’t about style, but it’s centred on comfort, quality, and even sustainability.

In this article, we will demonstrate how your business can expand by leaps confidently while maintaining consistency and complete customer satisfaction with custom clothing options. So, keep learning!

1) The Big Benefits of Custom Clothing

Wearing custom-made clothing is not only a way to dress up but also an investment in your well-being. Custom clothing pieces are thoughtfully created to accommodate specific body shapes and offer individual styles, providing physical and mental gains. Here, we are going to explain the benefits of custom-tailoring scientific knowledge to make it interesting.

Perfect Fit

First of all, keep in mind that your body functions best when it encounters no restrictive movement from clothing. Ready-made apparel is based on approximated general measurements, which, if they are too tight, can inflict considerable strain on your body.

Nonetheless, custom garments are stitched precisely to the client's measurements, which can range from 30 different areas like the neck, sleeve, waist, and shoulders. Hence, for a fashion brand, a suit business, or a local shop, your garments are guaranteed to fit better than off-the-shelf sizes.

Personalized Style

Moreover, with custom garments, customers have the option to choose the fabrics, colours, and designs for pieces according to their choice. From a scientific point of view, decisions based on personalised preferences tend to hold benefits for dopamine secretion, which is the happiness and motivation signal molecule.

Thus, I must say that the custom clothing acts as an external marker of identity. This helps solidify one’s self-image, which is crucial for young people.

Boosted Confidence

In addition, cognition and self-perception get a boost when wearing tailored clothing in personal style. I’m not saying this in the air, but science has proved this fact. In psychology, when we feel comfortable with our outfits, our mind gives positive reinforcement known as “enclothed cognition.” Thus, one tends to be more productive, begin to speak clearly and also show leadership skills.

2) The Quality Difference You Can See and Feel

Custom clothing's value comes from the investment made in it in its exceptional quality and durability. Each specific part of a custom garment is designed and constructed using high-end materials to best perform and outlast off-the-rack items. Because of this, custom shops as well as fashion businesses gain a reputation for providing genuine worth, beyond just fleeting trends.

Premium Fabrics That Last Longer

The use of polyester blends and other synthetic fabrics, commonplace in fast fashion clothes, is counterproductive due to a lack of longevity.

A report by the Ellen MacArthur Foundation states that more than half of the fast fashion market’s output (over 60%) is manufactured from plastic-based materials, and most of this category starts disintegrating after wearing it just seven times. This type of clothing has poor thermoregulation, rapid ageing, loses shape, and may feel hot against the skin.

But with custom clothing, your clients will have an option to select high-quality natural fabrics such as 100% cotton, wool, linen or silk, which breathe better and can absorb moisture far more efficiently than competing materials. These fabrics also enhance comfort and knitwear while enhancing durability over time.

Superior Craftsmanship, Stronger performance

Furthermore, clothing produced in bulk goes through a quick cutting and sewing process to save time at the expense of quality. Research in textile engineering shows that clothing can be poorly crafted to the point where it loses shape or tears after only a handful of washes ( 5 or 10 laundry cycles revealed by research in the textile industry).

However, extensive care is taken while making custom garments. Expert tailors reinforce high-stress areas such as the underarms and pant crotches using bar-tacking or double stitching. Through this sophisticated tailoring, your business gains an advantage to provide outfits that withstand daily usage while looking visually appealing.

Thus, a business committing to quality, custom-tailored clothes demonstrates brand loyalty, boosting trust associated with the company. If you are wondering how to customize clothes, then don't worry, you just need to contact a local manufacturer or online, like us.

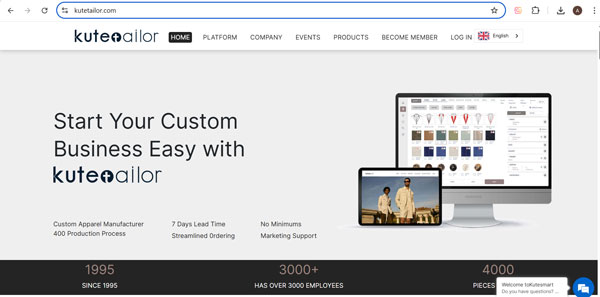

We at Kutetailor are custom clothing manufacturers for startups that supply customised formal, casual or women's apparel to a variety of the fashion industry for almost 30 years.

3) The Long-Term Value That Justifies the Cost

Initially, custom clothing may appear to be a large cost. Naturally, your customers might ask you one simple question: Why do I spend $400 on one jacket when I can purchase it for $100 at the store?”

However, as you are running your fashion business, I would say one thing: Set aside the price tag and consider practicality, then value becomes evident. Well, to satisfy your customers, I would like to introduce the idea of cost-per-wear.

Cost-per-wear is defined as dividing the total amount paid for an item by how many times it will be used. It clearly depicts what each use really costs. Consider these two jackets: one purchased from fast fashion stores and another from a tailor shop.

Price Wear Before Damage Cost Per Wear Fast-Fashion Jacket $100 10 wears $10.00 Custom-Made Jacket $400 100 wears $4.00 As shown in the table above, although the custom jacket has a higher initial figure due to the upfront price. But the extended longevity comes at a lower cost per usage. According to studies conducted on textile durability, most fast fashion items tend to expire in less than a year, while bespoke garments have an average lifespan of 5-10 years with proper maintenance. That offers immense value from just one piece.

Thus, this longevity puts a major hand in reduced returns and customer satisfaction, which in turn contributes to an improved brand image, too. Be it in small or bulk orders, this custom process enables you to provide fast and flexible bespoke clothing while maintaining quality.

4) The Ethical and Sustainable Edge

When your business customises garments, this means you are responsibly managing resources, people, as well as the planet, by offering superior value clothing. In today’s fashion world, sustainability and ethics are core pillars that customers and other stakeholders deeply resonate with. Custom tailoring allows businesses to communicate those expectations.

Skilled tailors or reputed sewing units operating in clean workplaces under humane conditions usually offer bespoke sewing. This differs from fast fashion, which relies on slave labour due to sheer volume demand and artificially low prices.

In addition, custom sewing adheres to a made-to-order principle, which eliminates the production of surplus inventory stock. The opposite approach is adopted by fast fashion retailers who just crank billions of units without regard to the market cap surplus of unsold units lying idle.

Industry studies claim that the global textile waste dumpster receives over 92 billion tons annually. Your business no doubt wants to be heralded as championing the cause of intelligent and reduced wasteful systems framework, devoid of supply chains.

5) Final Words

Nowadays, if you want to compete in the fashion market, you have to think about investing in custom clothing. As discussed throughout the article, custom clothing not only makes your customers feel comfortable, but this personalised dressing also helps in boosting self-confidence.

Moreover, the important point is quality, which is usually compromised in readymade garments. However, with custom clothing, your utmost focus would be providing the best quality, which in turn boosts the longevity of products and boosts your brand image.

Now, if you have made up your mind to start a custom clothing business, but are confused about how to get a custom clothing manufacturer, then just take a deep breath! We are just one tap away from you. We at Kutetaior provide high-quality and durable apparel products to the fashion industry, ensuring a transparent supply chain. So, explore our product range made to Measure Men's Suits!

MORE 2025-09-19 -

Laws and Regulations in the Fashion Industry: A Guide to Workplace Safety in Manufacturing

Laws and Regulations in the Fashion Industry: A Guide to Workplace Safety in ManufacturingIn the contemporary world of fashion, legal and workplace safety requirements have implications that reach far beyond ethics. They affect your image, clients' trust, as well as the affiliations with other businesses.

That’s why, in this article, we’ll provide insight into laws and regulations in the fashion industry. Whether you are a manager in charge of bulk production or are supervising small-scale production, it will enable you to maintain consistent quality, which helps in brand building.

1) Risks Involved in Fashion Workplaces

Fashion factories are active workplaces that have people literally working around the clock to manufacture clothes for consumers. So, let’s have a look at the risks involved in fashion workplaces to understand why safety standards matter!

Dangerous Machines: The high-speed operation of tools such as steam presses, fabric cutters, and sewing machines poses a dangerous risk to employees’ health. As you might know, steam presses can be very damaging if not used properly. Thus, ensuring them with simple operating rules is imperative.

Harmful Chemicals: Furthermore, a great number of dangerous substances are utilised in the production process. If your workers don't stay cautious, then there is the risk of sores forming along with lung damage.

Prolonged Working time: Furthermore, the absence of intervals during work sessions contributes to fatigue. When individuals start feeling fatigued and lethargic, it becomes increasingly challenging to mobilise the mental effort needed to perform even basic functions, which results in accidents and loss of productivity.

Hazards for Vulnerable Workers: Furthermore, women, foreigners, and teens often tend to miss out on getting equipment or decent safety training guidelines. Thus, putting them in greater danger without knowing their exposure level.

2) Key Global and National Regulations

Policies to protect health and safety in textiles have been implemented by both global bodies and local governments. Such laws intend to help prevent physical injuries to workers, improve occupational cleanliness, and maintain ordered control along and within the entire supply chain.

i) Global Initiatives

The International Labour Organisation (ILO) at the international level advocates for social labour rights through its several conventions. Let’s explore its conventions!

· Conventions 87 & 98 assure the rights of employees to establish unions and engage in collective bargaining towards better conditions at work.

· Convention No. 155 deals with occupational safety and health, encouraging employers to avert negligence towards risks.

· Convention 182 is directed towards the elimination of harmful child labour.

UN Guiding Principles

Apart from the ILO, the UN Guiding Principles on Business and Human Rights claim that businesses have responsibilities not only to respect rights of humans but also to reduce risks of harm within their corporate ecosystems.”

ii) Country-Specific Laws

Moreover, every national government puts the global standards into local and relevant policies. For example,

· The Bangladesh Labour Act covers worker safety, provision of exits for emergencies, and working hours limitations.

· The Factories Act in India also covers adequate ventilation and lighting as well as safeguarding relevant machinery.

· China’s Work Safety Law is focused on training employees on risk prevention and emergencies.

· Vietnam’s Labour Code mandates workplaces that provide break time, safe rest areas, donning of PPE (personal protective equipment), protective equipment during pauses, along with a safe working atmosphere.

However, there are differences between regions at the factory level when it comes to the enforcement of the rules set out above.

· Tier 1 factories that have direct dealings with international brands usually tend to comply with audits, along with rules set by the industry.

·While subcontracting, Tier 2 and Tier 3 factories operate under minimal oversight and scrutiny.

Apparel businesses can be aligned to operate within international regulations alongside country-specific legislations. They aimed at ensuring ethical breaches do not take place, thereby turning factories safer across various levels of operations.

3) Compliance and Safety Measures for the Fashion Industry

Factory inspections and adherence to safety regulations are done in an orderly way. A good breakdown of processes for attending to safety ensures that incidents, illnesses, and downtimes are greatly reduced. Let’s go on to have a look at textile safety rules!

i) Workplace Safety Standards

Basic safety begins with an appropriate layout of the factory. For instance;

It should include crucial components like working fire doors, proper buildings, spatial soundness, clean air flow mechanisms and working plus other tools necessary for the removal of dust and combined smoke.

Also, rotating machinery should be in working condition with guards that offer protective cover against mechanical injuries.

Moreover, according to OSHA, employees should wear PPE gloves, masks, ear shells, and head caps to match their duties with proper risk exposure.

Similarly, chemicals must be stored properly. For instncar; hazardous chemicals must have pertinent sign brackets placed while being isolated from common setup where they wouldn’t need special handling.

In addition, standard emergency response safeguards such as routine safety drills, first aid availability, and clear emergency plans bolster workplace safety.

Compliance Certifications

Many companies get third-party certifications as proof of commitment to safety and compliance:

· WRAP (Worldwide Responsible Accredited Production) reviews legal compliance, worker care, and ethics.

· SA8000 (Social Accountability International) deals with health, safety, and fair remuneration.

· The Fair Wear Foundation engages brands for improvement on safety and worker rights in high risk areas.

Improved certification aids seamless intercompany communication reinforcing alignment on goals relating to workplace safety.

ii) Environmental Compliance

In addition to workplace safety, the fashion industry must also comply rules for protection of environment. This is because it deals with several different operations involving different chemical processes.

Some processes such as dyeing and material treatment requires the usage of substances that can potentially harm human beings as well as nature. To alleviate these problems, there has been the introduction of cleaner production laws on an international and domestic level to softer and less harmful production in the fashion industry.

a) Textile Waste: The increased use of dies such as polyester has led to greater environmental pollution. These synthetic polymers, once dumped in landfills can last for hundreds of years which is extremely detrimental to the environment.

Law enforcements have forces these fashion industries to form recycling policies to cater them which is along the lines of circular economies where waste can be reused instead of thrown away.

b) Chemical Use: Hazardous chemicals are commonly used within textile industries, particularly azo dyes due to their carcinogenic tendencies. Furthermore, added presetments like formaldehyde wrinkles clothes but acts as an irritant and are suspected cancer causing chemical.

That’s why environmental regulations like ZDHC or reach (EU) try their best to remove any banable substances. It increases scales for plant based and biodegradable finishes becoming the preferred choice amongst most manufacturers .

c) Sustainability Claims: Claims such as “eco-friendly” and “non-toxic” are now more carefully scrutinized. To avoid greenwashing, these claims must be backed by scientific evidence.

For instance, cotton, which is labeled organic, must satisfy certification requirements such as GOTS. It ensures that the fibers have not been exposed to harmful chemicals or synthetic pesticides.

d) Carbon Footprint: In addition, producing clothing consumes a tremendous amount of fossil fuels that emit CO2. You know CO2 is a greenhouse gas that accelerates climate change. Companies are required to measure and document their emissions in several countries now.

Some countries use carbon taxes while others use cap-and-trade systems, incentivizing factories to invest in energy-efficient or renewable energy equipment.

e) Water Usage: Moreover, the dyeing process releases salts and water-soluble dyes which pollute rivers, resulting in the death of aquatic life due to low oxygen levels. This form of pollution can be mitigated with regulations that ensure pre-treatment such as neutralization, filtration, and oxidation before releasing water into the environment.

f) Ethical Sourcing: Lastly, the raw materials used must also adhere to safety and transparency standards for ethical sourcing. Synthetic fibers can have monomers derived from petroleum, while natural ones like cotton need to be sourced from farms that utilize responsible chemicals.

Brands can now prove the chemical safety and environmental responsibility of their materials thanks to digital traceability tools. If you’re looking for a custom apparel manufacturer that sticks to above mentioned compliances, then Kutetailor is the best option. We provide different apparel products, made to measure men's suits.

Conclusion

In a nutshell, if you are running fashion business, thne ensuring workplace safety must be your top priority. Thus, a lack of safety features on a factory floor can result in physical injuries and workplace accidents, like fires. For businesses, this could mean factory shutdowns, incurring legal costs, or losing trust from customers.

That’s why; many rules and regulations have been set in place, which we have discussed throughout the article. At KuteTailor- a custom clothing manufacturer, we know that the fashion for modern businesses relies on sustainable production. So, you can trust us to comply with certified eco manufacturing standards and international environmental regulations regarding your brand’s trust reputation globally.

MORE 2025-09-12 -

GOTS vs OEKO-TEX: What You Need to Know About Certified Fabrics

GOTS vs OEKO-TEX: What You Need to Know About Certified FabricsPuzzled by fabric labels like GOTS and OEKO-TEX? You’re not the only one. If you care for these tags that claim certainties like safe or organic. There is always some form of stress knowing what matters.

If the welfare of your kids' skin or the Earth matters to you, these certifications and understanding them are very helpful. In this blog post, I will tell you the actual significance of these two labels and how you can pick the best one that meets your requirements.

1) What Is GOTS Certification?

GOTS stands for Global Organic Textile Standard. It is an award or label of certification for a garment or textile. It informs you that the material has been produced in a hygienic and environmentally friendly manner.

First and foremost, the material should be composed of natural fibers such as organic cotton. This indicates that no harmful substances are utilized during cultivation. Thus, it is more beneficial for your skin and healthier for the environment.

Next, GOTS reviews how the fabric is produced. There are guidelines to maintain air and water pollution-free. Only non-toxic fabric dyes and no hazardous substances should be used for processing.

Moreover, GOTS looks after the welfare of its employees. Fair payment is the least that can be paid. Reasonable working conditions must also be in place. Most importantly, child labor should not exist.

Due to these restrictions, many quality companies utilize GOTS-certified textiles. If you wish to don garments that are considerate, safe, and environmentally friendly, this label is an excellent option.

2) OEKO-TEX Certified Meaning

OEKO TEX is a label that signifies safety. Its full name is OEKO-TEX Standard 100. It proves that a material has been analyzed and found safe to use. This label verifies whether fabrics such as garments, bedsheets, towels, and similar items contain toxic substances.

If this label is present on the product, it indicates that toxic chemicals such as lead, formaldehyde, and heavy metals are not included. This is the process: every component of a product undergoes testing, including threads, buttons, zippers, and even prints.

There are specialized laboratories that perform these tests. If all criteria are met, OEKO-TEX 100 certification is awarded. You can spot this label on numerous items such as infant apparel, t-shirts, socks, bed sheets, and even couch slipcovers.

It’s an ideal option if you are looking for something that is safe for your skin and your family. So, Oeko Tex Standard 100 assures you the product is clean and trusted.

3) GOTS vs OEKO-TEX: What’s the Difference?

Both GOTS and OEKO-TEX are certified labels that are trusted by people; however, they are not the same. Each label checks different aspects of textiles and follows different rules. In this section, we will discuss the difference between GOTS vs OEKO-TEX:

Feature GOTS OEKO-TEX Standard 100 Main Focus Organic materials and safe production No harmful chemicals in finished products Fiber Requirement Must have at least 70% organic fibers No need for organic fibers Checks for Chemicals? Yes, in dyes and process materials Yes, in all parts of the final product Cares for Workers? Yes, includes social rules and fair work No, focuses only on product safety Cares for the Environment? Yes, strict eco-friendly rules No, it does not check factory impact Common Products Organic clothes, eco-fashion, baby wear All textiles: clothes, sheets, furniture Elenora from Quora mentioned that the Global Organic Textile Standard (GOTS) is considered the top certification in the world for textiles that use organic fibers. It has extensive social and environmental criteria, monitoring each stage of the sourcing and production process.

She noted that the whole procedure is confirmed by third parties, which makes GOTS a trusted and reliable option for people concerned about sustainable and ethical production.

4) Benefits of GOTS and OEKO-TEX Certifications

Selecting fabrics with certifications goes beyond picking a product; it involves choosing safety, trust, and concern. Let us examine the main advantages associated with each certification.

Benefits of GOTS Certification

· Organic and Natural: Your skin and the world are healthier with organic fibers.

· Safe Production: Besides, no toxic substances are allowed in the procedure.

· Fair to Workers: Plus, fair wages and good working environments are ensured by GOTS, which protects the workers.

· People Still Trust It: Because of this, numerous brands turn to it for selling in international markets.

· Good for Sensitive Skin: Lastly, great for babies or anyone who suffers from skin allergies.

Benefits of OEKO-TEX Certification

On the other hand, OEKO-TEX places greater importance on safety concerns.

· Chemical Free Safety: It looks closely at every aspect of the product to ensure there are no dangerous chemicals present.

· Safeguards Wellness: For this reason, it’s effective for infants, minors, and grown-ups.

· Includes All Products: This tag can be found on other household fabrics like towels and bed sheets.

· Quick and Easy to Get: For many products, OEKO-TEX is quicker and easier than GOTS.

· Boosts Trust: Most importantly, it ensures purchasers that the product has undergone evaluation and is safe.

5) How to Choose the Right Certification for Your Needs

Confused about what fabric label suits you best? Be it for personal or business reasons, here we will discuss how to select the most suitable certification according to your requirements.

For Businesses (Brands, Sellers, Manufacturers)

· Select GOTS if you are selling organic apparel or sustainable merchandise.

· GOTS helps in reputation building with eco-conscious customers.

· Ideal for infant items, sustainable fashion, and international trade.

· Select OEKO-TEX if your priority is avoiding exposure to dangerous substances, even if the material isn’t organic.

· For a larger selection of products, OEKO-TEX certification is quicker and simpler to obtain.

· This certification works well for basic goods such as bedsheets, uniforms, and other household textiles. Businesses such as Kute Tailor leverage GOTS and OEKO-TEX certifications to provide safe, reliable, and high-quality fabrics for modern brands.

For Consumers (Buyers, Parents, Eco-Lovers)

· Pick GOTS if you are looking for clothes that are natural, organic, and safe for your skin while also protecting the planet.

· Suitable for sensitive skin, babies, and children; GOTS certifies healthy fabrics.

· Select OEKO-TEX if you would like apparel that does not contain dangerous chemicals, regardless of whether they are organic or not.

· Such labels prove wise when purchasing school uniforms, undergarments, or household textiles.

Final Thoughts

In Short, both GOTS and OEKO-TEX are valuable fabric certifications. If your priority is purchasing organic and eco-friendly garments, then GOTS is the best option for you. On the other hand, if your focus is on avoiding harmful chemical residues in textiles, then OEKO-TEX would be better suited.

Both of them assist you in making safer and more informed decisions. At KuteTailor, we prepare custom clothes that meet the GOTS and OEKO-TEX certifications. This indicates our products are effective, safe, environmentally friendly, and beneficial for you. Opt for fabrics that have certification, and you will surely feel the difference.

MORE 2025-09-04 -

Why Custom Fit Clothing Matters More Than Fashion: Understanding the Importance of Fit

Why Custom Fit Clothing Matters More Than Fashion: Understanding the Importance of FitSick of outdated fashion trends that just don't sit right? Well, you are not alone. Many tend to struggle with styles like pants pinching or shirts sagging. But the reality is that st yes, trends do come and go, but what really matters is having clothing that fits stylishly on any occasion.

In this blog, we will discuss how custom-fit clothing is much more important than fashion and how it can help you change the way you look and feel daily.

1) What Is Custom Fit?

Let’s start with a basic question: What does custom fit mean? It refers to clothing specifically tailored for your measurements. These garments are neither too big nor too small; they accentuate the right curves in your body and feel great.

For example, Custom t-shirts are made specifically using your height, weight, and body shape as measurements. Now, we will discuss how custom clothing differs from other types of clothing.

· Ready-to-Wear Clothing: First of all, ready-to-wear clothing is available in shops. Their size is categorized as small, medium, or large. However, these garments are crafted for a specific shape range, which may not be your dimensions. This is so because everyone's figure varies.

· Tailored Clothing: Next up, we have tailored clothing. Here, you first purchase ready-made clothes. After that, you take them to a tailor who alters the clothes to your liking. For instance, a tailor may reduce sleeve length and cinch the waist. This way, you get to enjoy better-fitting clothes.

· Custom Fit Clothing: Lastly, there’s custom clothing, which is also called made-to-measure clothing. These are more personal than the other two types since they are crafted using your very own measurements. Thus, they are perfectly tailored.

2) The Psychology of Fit: Why Good Clothing Fits Boosts Confidence

Have you ever put on an outfit and felt happy, proud, or even strong? That is the impact of good-fitting clothes. Good-fitting clothes can change your emotions as well as the way you feel about yourself from the inside out.

First of all, having well-fitted clothes on boosts your posture. You stand taller, walk more easily, and move more fluidly. Thus, you look confident without any effort at all. Also, wearing clothes that fit properly can improve your mood.

When you are feeling good and content with how your body looks, you don’t need to fidget or fix anything. There’s no tugging, just peace and fashion. Additionally, when clothes fit well, confidence increases. You stop worrying about the appearance of the outfit, and you start working on being the best version of yourself.

Above all, it’s not about having an ideal physique; it is about body inclusivity. Every shape and size, whether large or small, tall or short, deserves to have clothes that fit them properly. Made-to-measure means that your clothes can fit you seamlessly for the best comfort.

Businesses like Kutetailor offer made-to-measure clothing solutions, especially tailored to your measurements, making it effortless for you to have garments that fit your silhouette.

3) What Does Fitted Mean in Clothing?

You might ask, what does fitted mean in clothing? Fitted clothing means it follows the shape of your body, but it does not squeeze or hang. It sits nicely on your shoulders, chest, and waist, providing a clean trim appearance. In this section, we will see how fitted clothing differs from other styling options.

· Fitted clothing gently follows your body shape and isn’t too loose or too tight.

· Slim clothing is tighter to the body and usually tapers at the legs or sleeves.

· Tight clothing is very form-fitting as they are close to the skin. They often feel uncomfortable, under lots of pressure, and tense.

· Fitted offers balance because it gives you the right shape without making you feel suffocated. Fitted clothing serves many purposes, spanning from work to events and even daily activities. It is a smart choice because it improves posture as well as makes one feel comfortable while assisting in improving comfort levels.

Moreover, layering becomes simpler since one can wear a jacket or sleek bulged sweaters without bulk.

4) Custom Fit vs Fast Fashion

When purchasing clothes, you can choose between two options: fast fashion or customized fit. In this article, we will compare them to figure out which is better for you.

Point Custom Fit Clothing Fast Fashion How it’s made Made just for you using your exact measurements Mass-produced in standard sizes Fit Matches your body shape perfectly Often too loose or too tight Body type support Works for all body shapes Ignores unique body shapes Comfort Very comfortable, feels natural May feel awkward or tight Look Neat, polished, and well-shaped Can look messy or off Durability Lasts longer with better materials Wears out quickly Sustainability Less waste, made with care High waste, often not eco-friendly Cost in the long run Worth it, as it lasts longer It may cost more over time due to replacements 5) Why Fit Trumps Fashion Trends

Fashions always seem to change, and it can be difficult to keep up with the wide selection that is offered. One day, everyone seems to be wearing wide pants; the next, skinny jeans are making a comeback.

It is challenging to keep on track with everything. No matter what trendy style is in season, it will always be in for clothes that fit well. You always look polished when your clothing fits well. You don’t need the latest designs or bold colors.

A simple shirt that fits properly will always outdo a trendy one that’s ill-fitting. Even famous people and professionals understand this. A lot of them wear custom-fit suits, dresses, or shirts that match their shape.

Couturiers might not follow every single new fashion trend, but they're always sharp-looking. Why? Because the clothes fit.

6) How to Achieve the Perfect Fit (Even on a Budget)

Investing a lot of money does not guarantee that you will get clothes that fit well. With some easy changes, you can make the adjustment of your clothing effortless.

i) Tailoring Store-Bought Clothes

Start by checking the items in your wardrobe. If some of your clothes feel a bit loose or are too long, it is better to take them to a tailor. Simple alterations, indeed, like sleeve and waist adjustments, make a noticeable difference. It is more affordable than purchasing new clothes and ensures better-fitting garments.

ii) Try Affordable Best Online Custom Suits Services

Some websites offer made-to-measure clothes online for everyone at a reasonable price. A good example of this is Kutetailor. They provide made-to-measure options at low prices. All you have to do is send your measurements online, and they will create garments specifically for you.

iii) Measure Yourself at Home

Measuring at home can be quite easy. Simply grab a soft tape measure and do the following:

· Measure your chest from side to side at the widest section.

· Measure your waist at the area where you normally bend.

· Achieve the best set of results measuring hips at their fullest part.

· Record how long and wide your arms, shoulders, and even inseam are if necessary.

· Record and save the measurement details. These help in getting clothes that fit you both online and offline.

Conclusion

In short, fit is more important than fashion. Fashion fads change from one moment to the next. However, when your clothes fit well, you look and feel better all the time. Fit provides comfort first; it gives confidence second, and finally reveals true style. Instead of following several trends, opt for clothes tailored to fit you.

We understand the right fit matters; that’s why here at Kutetailor, we offer custom-fit clothing tailored just for you. It is simple, inexpensive, and designed to last long.

MORE 2025-07-25 -

Ensuring Brand Consistency in Custom Apparel: A Guide for Businesses

Ensuring Brand Consistency in Custom Apparel: A Guide for BusinessesIn the current challenging clothing industry, your brand is not only what you claim, but people’s perception about your brand matters a lot. Every inch of your apparel from logo positioning to fabric selection represents your business.

In this guide, I will explain how to maintain brand consistency across all custom garments. While doing so we’ll also make sure that the products look professional, feel harmonious, and durable as well as have an impact after use.

1) What is Brand Consistency, and why does it matter in Apparel?

“Brand consistency means maintaining the same styling and messaging visuals across all platforms and products, including the logo, colour scheme, typography, and tone of voice.”

A unified brand identity allows customers to know what to expect every time they engage with your products. Moreover, studies in neurobranding suggest that it takes just 400 milliseconds for a first impression through visual branding.

Why is consistent branding important in apparel?

Clothing as a Touchpoint Marketing: Well! Apparel isn’t merely a product to buy; however critical to note that it embodies history, representing a company physically over some time. However, you have to make constant changes to the logo, fit, or fabric style. It will dilute your brand’s impact and create confusion for clients.

Builds Trust and Recognition: Moreover, as customers recognise your brand due to consistency in the clothing's design elements as well as the packaging, they begin to trust it. This is essential for B2B buyers and fashion retailers who value reliability when placing repeat orders or establishing long-term partnerships.

Supports Scalable and Customizable Production: Last but not least, for custom shops or trading companies, sustaining uniformity within small or diverse orders helps scale efficiently. Clear branding guidelines help reduce production mistakes, streamline turnaround times, enhance satisfaction levels, and boost customer retention.

2) 6 Tips to Ensure Brand Consistency in Custom Apparel

Your brand image plays a crucial role in how people perceive it. In this scetion, I’m going to suggest to you some smart tips that will help maintain consistency across every product you create.

Tip #1: Stick to Your Brand Colours and Logo Specifications

As already discussed, everyone recognises a business by its branding logo. So, what do you think about the logo? Well, it's your brand’s face, and new customers first notice the colours whether it's your products, websites, or tags.

For instance, if you sold two blue jackets made under the same brand, but their blue shades are different, then your brands look unreliable. So, you must have to use exact colour codes like Pantone ( a universal colouring system used in textile printing), CMYK ( Cyan, Magenta, Yellow, Black-uses in ink printing) or RGB (Red, Green, Blue- used on screens) colour schemes.

Also, ensure logos always remain in predesignated spots at designated sizes relative to the surroundings. These are little things, but if left unnoticed, they can cause drastic effects on your brand’s image.

Tip #2: Choose the Right Fabric to Match Your Brand’s Feel

Additionally, your selection of materials also reflects the ethos of your brand. For example, a high-end label would opt for premium cotton or wool. In contrast, an eco-friendly brand is likely to prefer recycled or organic fabrics. These decisions help consumers make sense of your brand values, even before donning the apparel.

Thus, if you’re showing you’re an eco-friendly brand and thus using the same fabric across all your products, then this uniformity in fabric selection enhances affinity towards products. Thus, giving customers a consistent good experience each time.

Tip #3: Maintain Consistent Typography and Messaging

Also, Typography ( styling of words like font, size, colour) and messaging ( words and letters describing particular things) are important. Here, the point to be noted is that spelling out statements using various fonts and sizes will only serve to confuse rather than bring order.

So, whether it’s care labels or packing boxes, all should be uniform without differing, as they all represent a company’s name.

Let’s take an example for better understanding! Suppose your brand portrays bold modern elements. Then match it with clean, sharp wording yielding desired effects. Alternatively, if you take softer approaches, then your brand style and messaging must be like giving calm, classy, yet equally polished vibes. Clear!

Tip #4: Guarantee Quality and Suitability Align with Your Brand Principles

Furthermore, people will perceive everything about your brand based on the feel and fit of your clothes. It’s a Universal fact that even the best designs are rendered useless if there is poor construction or inaccurate sizing.

For example, as a luxury suit company, the finishing must be structured, tailored, and crisp. If you offer casual or sportswear, the priorities shift to comfort and flexibility. If one shirt is sized correctly, they will expect the same for subsequent shirts. This cultivates trust, which is very important while managing bulk orders alongside small ones.

Tip #5: Use a Trusted Custom Apparel Partner

A great design loses its value when a vendor misfollows instructions when creating a garment piece. That’s why you should work with a partner who understands branding, not just how to sew or print. But they should get all-in-one jobs right, i.e., matching colours and fabrics and following guidelines every single time without fail.

So, I would recommend asking for digital mockups, fabric swatches, and regular updates during production so that everything runs smoothly and prevents expensive blunders from happening.

At KuteTailor, we understand the varying needs of your fashion brand, trading company, or design business with our tailored methods. Whether it’s formal custom wear, casual dresses, or women’s apparel, we have you covered.

Tip #6: Document and Standardise Apparel Branding

Every brand has its dos and don’ts on how to present itself, which are called rules in brand governance. These vary from every fabric selection to logo placement, thus contributing to building this guide.

Therefore, brand guides need to be comprehensive so they’re easy to follow, like outlining approved colours alongside text formatting for colour schemes and typography ratios, font choices, as well as logo size and placement. Thus, if you’re running a fashion business and working with multiple store vendors or franchises, then these comprehensive guidelines enable standardisation across regions.

3) From Consistency to Authenticity: The Next Step for Your Brand

Brand consistency “is the starting point”; customers can easily recognise, trust, and remember you. However, in today’s markets, trust alone is not sufficient. People now want more than just a shiny logo; they want something that they believe in. This is where authenticity crosses over as your next big leap.

Now that you have established visual branding through logos, fabric,s and fit, ask yourself:

· Do your materials reflect your values?

· Does your design say something about who you are?

· Do your products make clients proud wearing them?

If one claims eco-consciousness as a selling point, then their apparel needs to embody organic or recycled materials. These statements should be actionable instead of mere words meant for marketing slogans. The agreement of what you speak and the actions you take is what gives rise to authenticity. Got it!

Thus, a brand needs a production partner to gain a deeper understanding of brand perception beyond fabric and fit in order to achieve authenticity, as opposed to consistency. This explains why numerous fashion enterprises select Kutetailor- a custom apparel manufacturer.

Final Verdict

From all above discussion, we have reached to conclusion that brand’s concistency plays an important role in building trust among clients. Whether you’re running custom apparel business or any other unifromity across every product help people remember your brand, thus chances of reppetiove buying contributing to revenue increase.

However, among all, finding a trusted production partener is equally importent. So, look no furthur than Kutetailor. We as a custom apparel manufacturer have years of experiebce in the production line custom clothing for both men and women.

We support your efforts not only towards making consistent clothing but also curating collections that illustrate the narrative of your brand—be it sustainability, graceful elegance, or audacious boldness. So, visit us now

MORE 2025-07-04 -

Selvage Denim: Why It’s the Best Choice for Custom Jeans

Selvage Denim: Why It’s the Best Choice for Custom JeansWhen it comes to creating custom jeans that are durable, comfortable, and unique, the choice of fabric plays a pivotal role. Among the various fabric options, selvage denim stands out as a premium choice for those who demand the best in quality and craftsmanship. Unlike regular denim, selvage denim is woven using traditional shuttle looms, giving it a distinctive edge and a higher level of durability. This article explores what selvage denim is, its advantages for custom jeans, and why it should be the fabric of choice for anyone looking to invest in high-quality, custom-made denim.

What is Selvage Denim?

Definition

Selvage denim refers to denim fabric woven on a traditional shuttle loom that creates a self-finished edge, known as the "selvage" edge. This edge is tightly woven, which prevents it from fraying, ensuring the longevity of the fabric. Selvage denim is known for its superior craftsmanship and durability, making it a popular choice for high-end, custom jeans.

History

The origins of selvage denim date back to the 19th century when it was first created by shuttle looms. Unlike modern looms, shuttle looms produce narrower rolls of denim with finished edges, resulting in cleaner seams and a more durable fabric. Over time, selvage denim became synonymous with premium, handcrafted denim products, especially in the era before mass production took over. Today, selvage denim remains a staple in high-quality denim production.

Difference from Regular Denim

The primary difference between selvage denim and regular denim is the production method. While selvage denim is made using a shuttle loom that produces a clean, tightly woven edge, regular denim is often woven on a projectile loom, which results in frayed edges. This difference in weaving techniques gives selvage denim its distinct edge and high-end quality.

The Advantages of Selvage Denim for Custom Jeans

Unique Edge Design

The self-edge design of selvage denim is one of its most distinctive features. The tightly woven edges enhance the durability of the fabric, ensuring the jeans' longevity. This design also adds to the aesthetic appeal, as the raw edges are often visible on the inside of the jeans, showcasing the craftsmanship involved.

Durability

Selvage denim is more durable than regular denim because of its dense weave and strong edges. This makes it ideal for custom jeans, as it can withstand regular wear and tear, ensuring a longer lifespan compared to jeans made from regular denim.

Comfort

Despite its sturdy nature, selvage denim offers excellent comfort. The fabric softens over time, molding to the wearer's body for a personalized fit. This makes it particularly appealing for custom jeans, where comfort is key.

Why Selvage Denim is Ideal for Custom Jeans

Perfect Fit

Because of its high quality and rigidity, selvage denim helps create perfectly fitted custom jeans that are tailored to the customer’s body. The durability ensures that the jeans retain their shape over time, even after multiple washes, making them ideal for customers who want a long-lasting, well-fitted product.

Premium Look and Feel

The unique edge and high-quality finish of selvage denim give custom jeans a sophisticated, premium look that is difficult to achieve with regular denim. This adds a level of refinement and exclusivity to each pair of jeans.

Personalization

One of the key benefits of using selvage denim for custom jeans is the ability to personalize every detail. From the perfect fit to the selection of color, wash, and finish, selvage denim allows customers to create jeans that are uniquely their own, ensuring no two pairs are alike.

The Difference Between Selvage Denim and Regular Denim

Manufacturing Process

Feature Selvage Denim Regular Denim Weaving Method Shuttle loom, creates a self-finished edge (selvage) Projectile loom, frayed edges Fabric Quality Denser, more durable fabric Lighter, less durable fabric Edge Finish Tightly woven, clean edge Unfinished, raw edges Visual Differences

Selvage denim’s distinctive self-edge design gives custom jeans a clean, finished look, making them stand out with a premium appearance. Regular denim lacks this distinctive edge and often appears less refined in comparison.

Price vs. Value

Selvage denim tends to be more expensive due to the slower, more intricate production process. However, its durability, quality, and unique design justify the higher cost. When compared to regular denim, selvage denim offers better long-term value for custom jeans.

How to Choose the Right Selvage Denim for Custom Jeans

Fabric Thickness and Texture

Choosing the right thickness and texture of selvage denim depends on the desired look and feel. Lighter denim is ideal for summer jeans, while heavyweight denim is perfect for winter jeans that need added warmth and durability.

Color and Style

Selecting the right color, wash, and style of selvage denim is essential for creating the perfect custom jeans. Whether you prefer a raw, unwashed look or a faded, pre-washed design, the possibilities are endless.

Details and Finishing

When creating custom jeans or custom formal wear, it’s essential to incorporate the right stitching, buttons, and design elements. Opt for unique finishes like contrast stitching or copper rivets to enhance the overall look of your custom jeans. For formal wear, sleek details like matte or polished metal buttons and understated stitching will add a subtle touch of elegance, ensuring the jeans or pants maintain their formal appeal without sacrificing comfort.

Sustainability and Environmental Impact of Selvage Denim

Environmental Benefits

The production of selvage denim typically results in less waste compared to regular denim, as it is made with a more traditional and sustainable weaving process. Additionally, selvage denim tends to last longer, reducing the need for frequent replacements.

Comparison with Fast Fashion

In comparison to fast fashion denim, selvage denim is a more eco-friendly option. It’s produced using fewer chemicals and less energy, making it a more sustainable choice for environmentally conscious consumers.

Conclusion: Why Selvage Denim is the Best Choice for Custom Jeans

Selvage denim offers the perfect combination of durability, comfort, and premium appearance, making it the ideal fabric for custom jeans. Whether you’re a custom apparel manufacturer seeking to create a unique fit or a consumer looking for personalized design, selvage denim ensures high-quality craftsmanship and long-lasting wear. Additionally, its sustainable production process makes it an eco-friendly choice, offering a refined and durable alternative to regular denim. For manufacturers and designers, choosing selvage denim allows you to deliver a product that not only meets the demand for quality but also elevates the overall customer experience.

FAQs

Is Selvage Denim More Expensive than Regular Denim?

Yes, selvage denim is generally more expensive than regular denim due to the more labor-intensive production process and higher quality of the fabric. The use of traditional shuttle looms, which produce the tight self-edge, results in higher production costs, but the long-lasting durability and unique qualities make it worth the investment for custom jeans.

How Do I Care for Selvage Denim Jeans?

Caring for selvage denim involves a few key steps:

· Washing: Wash selvage denim less frequently to preserve its structure. When washing, turn the jeans inside out to prevent fading.

· Drying: Air-dry your jeans to prevent shrinking and maintain their shape.

· Breaking In: Selvage denim tends to soften over time as it molds to your body, so wear them regularly to break them in.

Can Selvage Denim Be Used for All Types of Custom Jeans?

Yes, selvage denim can be used for a wide range of custom jeans styles, from classic straight-leg jeans to more fashion-forward skinny or tapered fits. Its versatile nature makes it an excellent choice for any custom jeans, as it provides a durable, high-quality fabric that molds to different cuts and styles.

Is Selvage Denim Environmentally Friendly?

Yes, selvage denim is more environmentally friendly than mass-produced denim. The production process is more sustainable, as it uses less energy and results in less waste. Additionally, selvage denim tends to last longer, which reduces the need for frequent replacements. Choosing selvage denim is a more eco-conscious choice compared to fast fashion alternatives.

Can I Use Selvage Denim for Other Clothing Items Besides Jeans?

Absolutely! While selvage denim is most commonly used for jeans, it can also be used for other custom clothing items such as jackets, skirts, and even accessories like bags or aprons. The durability and unique look of selvage denim make it a great option for creating high-quality, long-lasting apparel beyond just jeans.

MORE 2025-07-03